THE ITALIAN LUSTER at Munich Fabric Start

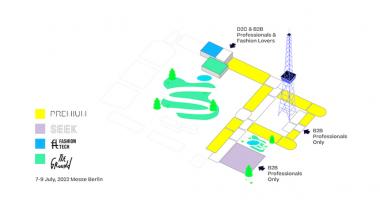

Munich Fabric Start presents a new project-area that will take place during the next edition.

BLUEZONE with CATALYZER and KEYHOUSE will be the place to be for the blue community on 30 and 31 August. As a global key event for the denim industry, 90 international denim mills, weavers, manufacturers and suppliers will show their latest innovations and trends in the Zenithhalle, the Kohlebunker and the Kesselhaus.

"THE ITALIAN LUSTER" will offer all visitors a deep dive into the Made in Italy supply chain with companies that have turbocharged growth by focusing on quality, innovation and research. Well-known and international companies that can make an important contribution to European and global brands.

From the production of trimmings and accessories, to the creation of unique fabrics, to the inspiration of new collections and their realization to the finishing of the garments, Made in Italy still represents the reality par excellence focused on ethical and sustainable production.

"THE ITALIAN LUSTER" will allow all visitors an incredible journey into the Italian supply chain that has the ability to meet any demand of brands, from small to large production needs.

On the top floor of the Catalyzer Hall, it will be possible to view the individual collections of the companies in attendance and receive a beautiful gift specially created by the CADICA GROUP company from Carpi.

Participants

ACM - TRIMS AND ACCESSORIES PRODUCER

ACM was founded in 1982.

Since 1982, ACM has been providing the fashion world with unique, sought-after and customized details, guaranteeing prestigious and innovative workmanship. Each and every product is the result of the care we take at every stage of our production process: from the prototype, designed by putting the consumer's health first, to production with state-of-the-art machinery, which allows for fine workmanship and cutting-edge customization, while minimizing the impact on the environment (we are GRS certified) and complying with the strictest eco-toxicological regulations.

FASHION ART - LUXURY FASHION DESIGN

Fashionart is the brainchild of Andrea Rambaldi, who, after learning his trade from his parents, his mother a seamstress and his father the owner of a dye shop, decided to pursue a freelance career.

He began by collaborating with companies in the textile sector, where he deepened his knowledge in the field of chemistry and industrial processes, touching on the problems of processing cycles.

The real turning point came as a result of an important job for the Maison Chanel, which recognized the originality and effectiveness of his technical proposals. From that moment, this is 2008, FashionArt was born, a company focused on luxury fashion and design, expert in the design and production of garments.

From the idea to the final product, the company is able to support the client throughout the entire production process.

Since then, the company has grown and developed exponentially thanks to a team of managers, artists and experts whose experience makes them a benchmark in the high fashion industry. Fashionart operates exclusively in high fashion, a very difficult field in which to combine experience and technique with art and creativity, where our potential can be expressed to the fullest.

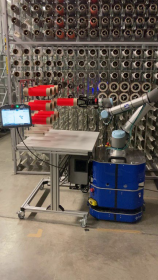

ELLETI - GARMENTS AND WASHING MAKER

Advocate of an approach that combines tradition, creativity, and innovation, for over 30 years Elleti Group has defined standards of absolute excellence for the denim industry. Born in the 80s in San Bonifacio, near Verona, the company developed in a one-of-a-kind context, a hotbed of ideas that led to the defining and establishing of new professions and skills in the field of denim treatment and garment personalization. Led by Luigi Lovato, right from the start the company established itself on the denim scene thanks to an ambitious and pioneering investment in new solutions. The following ten years mark an important growth which leads to the internationalization both of brand and production. After the implementing of a new department for garment dyeing, Elleti Group was ready to welcome the ever-increasing international demand, equipping itself with the first laundry in Tunisia, a country logistically central in the Mediterranean area, and as a result, ideal for the development of a complete textile supply chain. This successful story continues to unfold in the 2000s, a decade that marks the opening to the market of garment making thanks to two new structures in Romania, and peaks with the acquisition of Martelli Lavorazioni Tessili. Today Elleti Group stands firm in the market as a result of a complete offer that preserves the company’s artisanal vocation enriched through a constant process of responsible innovation.

In addition, companies BERTO INDUSTRIA TESSILE and OLIMPIAS GROUP will participate in the project by presenting their collections within their booths in the Catalyzer hall.

EFFE-BI SRL PR & COMMUNICATION