Avgol® showcases Algaeing™ bio-based colorants and fibers at FILTECH

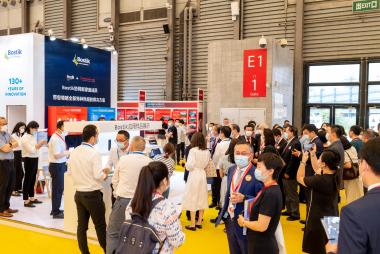

Avgol®, a manufacturer of high-performance nonwoven fabric solutions, will use this month’s FILTECH exhibition in Germany to showcase its latest developments in using Algaeing™’s patented algae bio-based formulations for colorants and fibers.

Together with its sister companies from Indorama Ventures Limited (‘IVL’), Avgol will be presenting biotransformation capable fibers and meltblown for diversified end-use markets at the event from 14-16 February. Avgol will discuss with visitors how this new technology and the company’s biotransformative products can help businesses achieve their 2030 sustainability goals.

Algaeing’s technologies utilize various sustainably sourced, vertically farmed algae species to produce a wide range of appealing colors, many of which replicate the colors used in nonwoven fabrics today.

“The benefits of using an algae bio-source go far beyond the removal of chemically synthesized colorants, and include synergistic benefits of vastly reduced water consumption, chemical and fertilizer use, and carbon dioxide emissions,” says Avgol CEO Tommi Bjornman. “We will be demonstrating to FILTECH visitors that following an extensive development path, the fibers both absorb and retain a range of colors - such as vibrant greens and blues – and that we can even deliver a ‘heathered’ appearance for a more natural looking material, all without affecting the filtration, barrier quality or feel of the final product.”