Rieter with New Group Structure: Annual savings CHF 30 million

The planned acquisition of the “Barmag” Division of OC Oerlikon will create the leading system provider worldwide for natural and man-made fibers. Rieter is confident it will receive all regulatory approvals to complete the acquisition in the fourth quarter of 2025. The Rieter Group is therefore adjusting its Group structure as of January 1, 2026, to take this acquisition into account and to be able to provide an even more agile response to market challenges.

The Machines & Systems and After Sales Divisions will be merged. Alexander Özbahadir will take over the new “Short-Staple Fiber” Division, which will be responsible for the short-staple fiber business, effective January 1, 2026. This will create synergies in sales and service activities and increase customer centricity through a geographical focus.

Roger Albrecht will now be responsible for the “Components and Technology” Division. His mandate will be to develop pioneering technology solutions, drive innovation and achieve growth in the key components business. With this organizational change, Rieter will further expand its technology leadership and intensify its development activities between Rieter and the component companies Accotex, Bräcker, Graf, Novibra, Suessen, SSM and Temco.

Serge Entleitner has decided to step down from the Group Executive Committee, effective December 31, 2025, and will support the company on various projects until his retirement in 2027.

Upon successful closing of the Barmag acquisition, the “Man-Made Fiber” Division will be integrated into the Rieter Group. Georg Stausberg will continue to lead the division and report to Thomas Oetterli, CEO of Rieter. He will also take a seat on the Group Executive Committee.

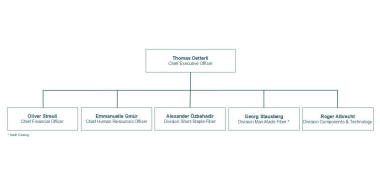

As of January 1, 2026, the Rieter Group Executive Board will comprise the following members:

- Thomas Oetterli, Chief Executive Officer

- Oliver Streuli, Chief Financial Officer

- Emmanuelle Gmür, Chief Human Resources Officer

- Alexander Özbahadir, Head of the “Short-Staple Fiber” Division

- Georg Stausberg (after closing), Head of the “Man-Made Fiber” Division

- Roger Albrecht, Head of the “Components and Technology” Division

Rieter is responding to the persistently weak market situation with further cost-cutting measures by adjusting production capacities, simplifying supply chains, and streamlining overhead functions. The estimated one-off costs of around CHF 30 to 35 million will result in annual savings of just under CHF 30 million.

Rieter AG