Circularity and Fashion: Interview about the Business and Communication Platform Neonyt

Circular instead of throwaway economy - from fast fashion to zero-waste philosophy. The key elements of the circular economy in the fashion business are: Avoiding waste and pollution through new processes, continuous recycling of products and materials, and regeneration of natural systems. Textination talked with Olaf Schmidt, Vice President of Textiles & Textile Technologies, and Thimo Schwenzfeier, Show Director of Neonyt, from Messe Frankfurt about the Neonyt trade show as a business and communication platform for circularity & fashion.

It has been about 10 years since Messe Frankfurt ventured onto the "sustainable" fashion trade show stage. Initially with the Ethical Fashion Show, then with the Greenshowroom, there were two trade show formats in Berlin dedicated to the topic of green fashion. What prompted you as a trade show organizer to launch such a special format in Germany at that time?

Olaf Schmidt: Messe Frankfurt's Texpertise Network brings together the world's most important textile trade shows - at around 60 events worldwide, we show what drives the textile and fashion industry. We present the current topics and trends and set impulses for the entire textile value chain. Messe Frankfurt recognized the need for a suitable platform for the future topic of sustainability at an early stage. It was therefore obvious to expand our expertise in the field of fashion and to meet the demand from this segment. To achieve this, we have adapted and realigned existing formats: After launching the Ethical Fashion Show in Paris in 2004, Messe Frankfurt France took over the event in 2010. Two years later, Messe Frankfurt founded the Ethical Fashion Show Berlin in Germany and found, with the moving of the event to the polarizing capital, the ideal location for the coming years. Messe Frankfurt merged the already existing Greenshowroom with the Ethical Fashion Show, and from January 2015 the two shows took place in one venue. For Messe Frankfurt, hosting these events was the next logical step on our way to a sustainable fashion future - the concept is now established in the sustainable fashion market and has a continuous growth potential. The merging of the trade show duo in 2019, with the current name Neonyt, allowed us, our exhibitors and visitors a new content orientation and a holistic approach to the topic of sustainability as well as a more direct access to the conventional fashion market, especially with regard to retail. In summer 2021, Neonyt will take place for the first time in the new fashion hotspot Frankfurt as part of the new Frankfurt Fashion Week.

In 2019, both event formats were merged, the new trade show Neonyt was born and 1 + 1 became what? What components does Neonyt offer in addition to the previous trade show concepts, what is so "new-new" and how did you actually come up with the name?

Thimo Schwenzfeier: One plus one, as you so nicely put it, did not simply add up to two with Neonyt. One plus one equals unique, neo-new, internationally relevant: Among other things, the trade show business was supplemented by the international conference format Fashionsustain and a showcase to gradually bring

together the topic of sustainability with the topics of technology, innovation and prepress. Our content creator format Prepeek ensures the necessary lifestyle and the fashion show provides the glamour of the fashion world. Neonyt combines the most important elements of the international textile and fashion industry - style, business, inspiration, innovation, knowledge, fun and community. And that is exactly what makes Neonyt so "new-new". Progressive and polarizing - the artificial word Neonyt is derived from the ancient Greek word "neo" (eng. new, revolutionary) and the Scandinavian word "nytt" (eng. new). "The renewed new" - Neonyt is our synonym for the fundamental transformation process of the textile and fashion industry, a reinterpretation of what has already been there and our commitment not to stand still and to promote positive change together.

For the Neonyt trade show format, you have teamed up with partners - for example, for conferencing components and in the design area. What expertise do they provide, and what is the added value for exhibitors and visitors?

Thimo Schwenzfeier: We know which future topics our brands and the community are currently dealing with and therefore create the right platform - for personal encounters and exchange, for networking and successful business deals. To put it simply: we organize trade shows, we organize events, we provide the right setting, we connect people and business. Neonyt therefore forms the global interface between the various players in the textile and fashion industry - between industry, trade, politics, services and consumption. And so that a lively, transparent and, above all, authentic dialog can develop between all counterparts, we naturally draw on the knowledge of industry experts and form strong partnerships to push fashion and sustainability forward. Only together can we achieve real change and guarantee that our community is provided with sufficient and, above all, the right information to make self-determined decisions.

In recent years, the keyword circularity - or rather closing the loop - has been encountered everywhere in the fashion industry. Whether Stella McCartney, the Ellen MacArthur Foundation, or large retail groups - many players and decision-makers are of the opinion that the future of the fashion world lies only in a circular economy and not in downcycling of any kind. What is Neonyt's view on this?

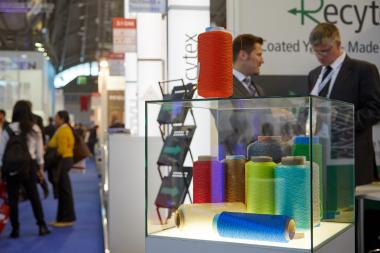

Thimo Schwenzfeier: That's right, the concept of circular economy is not new, nor is it limited to the textile and fashion industry. Circularity - actually the ultimate for every product, every industry, for our global society. The concept is supposedly simple: All materials and products are kept in a closed loop, the useful life is increased and at the end of the product life cycle everything is recycled. Many sustainable fashion labels are already showing how it's done. Neonyt brands are right at the forefront and are already implementing practices that should become the norm as soon as possible: starting with T-shirts or shoes made from recycled materials and take-back systems for collection items. As well as compostable clothing that "dissolves" at the end of the product life cycle and breaks down into its natural components, and on to repair services and leasing models for denim and co. - thinking holistically, acting in a sustainable manner and producing in a circular way are definitely the trends of the coming fashion seasons and at least one important, if not the most important, component of the future fashion world.

For the idea of a circular economy to be implemented successfully, there needs to be an interplay between technology, production, design and sales. What presentation options and forms of communication does Neonyt have in store for the various components?

Thimo Schwenzfeier: The combined innovative power of technology, sustainability and digitization is an important driver of the current developments in the textile and fashion industry - including the topic of circularity. Processes and production sequences are changing along the entire value chain - the industry has to reinvent itself for the most part. Neonyt shows how this can work successfully in the long term, with the internationally established Fashionsustain conference format - including spin-offs in China, Europe and the USA - and the supplementary Showcase. Together, these two formats offer the ideal mix of orientation and inspiration to prepare the industry for the future. Virtual fashion, authentic brands and textile value chains, science and innovation as well as retail, business models and impact investment - at Fashionsustain, top-class experts will exchange ideas with an interested professional audience and discuss the change and new solutions in the textile and fashion industry. The Neonyt Showcase takes a deeper look at the topics and innovations presented and discussed on the Fashionsustain stage. Expert knowledge on-demand, so to speak: whether microfactories or installations - Neonyt brands as well as brands from the rest of the Texpertise Network of Messe Frankfurt, such as exhibitors at Texprocess, get the chance to present sustainable innovations, new technologies and materials, initiatives, change-maker campaigns or research projects. Here they interact directly and practically with Neonyt's international cross-sector community.

Last year was an unprecedented challenge for trade show companies due to the pandemic situation. Neonyt was also affected by this - and physical events had to be canceled. With a digital format "Neonyt on Air" you have tried to offer exhibitors and visitors an alternative platform. What has been your experience: Did the focus of the trade show and its community perhaps even help to make such a virtual event easier to launch?

Olaf Schmidt: Corona has already changed a lot and will certainly continue to do so in one way or another. Nevertheless, it will continue to be our task as trade show organizers to offer the industry the best possible meeting platforms for presenting their new products worldwide. We are convinced that people will continue to want to meet in person and discuss new products as well as services in the future. This is particularly the case in the textile sector, where haptics plays a very crucial role. We expect that there will even be a certain catch-up effect after the crisis. Because what the last two very successful digital seasons of Neonyt on Air, for example, have nevertheless shown clearly: Fashion lives from personalities, presentation and inspiration. Digital formats can support this, but they cannot fully replace it.

Thimo Schwenzfeier: The digital Neonyt on Air was far from being a total replacement for the original physical seasons, but nevertheless a huge success. For one week, fashion, lifestyle and digital experts were discussing about more authenticity, immediacy and transparency in the textile and fashion industry in numerous keynotes, interviews and panel discussions. With more than 24,000 international followers on Instagram, we generated around 50,000 impressions and more than 4,700 content interactions with our presenting partners Grüner Knopf, Hessnatur and Oeko-Tex in just five days. These figures show, that the topic of sustainability has arrived in the middle of society and is being discussed across all industries. I think that the polarization and, above all, the prevailing restrictions, as far as trade and commerce are concerned, have certainly contributed to holding a successful digital format. Digitization was truly the booster for the fashion industry in this case: Instead of replacing personal exchange, it helps to maintain and expand the business activities of brands, especially in the current times. And quite clearly, the need for exchange in the fashion industry and the motivation to initiate together a change are still enormous. Neonyt on Air has once again shown us that clearly. However, we are already looking forward to the next physical edition of Neonyt.

The COVID-19 pandemic has also left its mark on the textile and clothing industry. When you look back on just under a year of "state of emergency" - what positive experiences do you take with you, where do you see a need for improvement, for what support are you grateful for and where did you feel you were left on your own?

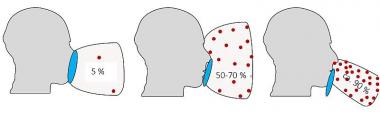

Olaf Schmidt: A year like no other - that can clearly be said about the last one. The Corona pandemic caught everyone off guard - us as trade show organizers, but of course also our exhibitors, visitors and partners. Especially in the near future, we must continue to expect, that trade shows can only be held under stricter health and safety regulations at first. Messe Frankfurt reacted quickly and developed a comprehensive safety and hygiene concept. One thing was clear: we all had to adjust and deal with a new situation. And so far, we've done a great job together, the team understanding among each other, the close contact - although physically at a distance, but globally networked - between all those involved, makes me feel positive about the future. For me, an important realization of this global pandemic, a credo almost, is to be open to new ways and opportunities and to find ways to combine things rather than separate them: Hybrid solutions, so to speak.

Thimo Schwenzfeier: There was no master plan for Neonyt, and in places there was also the impression that we now had to "reinvent the wheel": How does collaboration work when face-to-face meetings cannot take place? Can digitized contact compensate for the social distancing that is currently being imposed and still make it possible to work closely together? How can business relationships be maintained when stores are closed? How can priorities be set when well-tested solutions and established annual plans lose their validity? Who am I, who are 'the others' and what defines community? Never have questions about our creation and existence, about what makes us who we are and what we want to be, been more relevant than right now. One thing that I take away from the current situation and that allows me to continue to look forward positively despite difficult circumstances is the fact, that cohesion and solidarity with one another - both privately and professionally - have become increasingly important. Like a magnifying glass, the crisis has magnified existing opportunities, but also challenges, and brought the essentials into focus. I think that if we continue to try to experience things more consciously and not take them for granted, we will manage together to create a " new normal " and leave this crisis with more strength.

As in the past in Berlin, Neonyt is currently also located in Frankfurt in the environment of the Fashion Week and conventional trade shows. Can you imagine that a special event concept like Neonyt will be unnecessary in a few years, because the circularity concept will have established itself in the clothing industry worldwide?

Olaf Schmidt: A clear no. Sustainability per se is already no longer a unique selling point. The important thing is to keep up with the times, to follow trends or, even better, to track down new trends yourself and develop them further. Things, strategies, concepts will always change - if last year showed us one thing, it was certainly that. It is more than desirable that we all learn from this crisis and reflect on the really important values, on solidarity between partners, on climate protection and sustainability. It may be exactly for this reason, that companies that place particular emphasis on sustainability will emerge even stronger from this crisis. So you can be sure that we, as a leading international trade show organizer for the textile industry, will continue to focus on sustainability and support future-oriented companies and solutions. However, this will not make our formats obsolete due to the establishment and normalization of holistic business practices in the textile industry. But it is impossible to make an exact forecast for the coming decades. Over the last few months, we have all noticed ourselves in our personal everyday lives or in our professional lives, how uncertain and volatile the future is. What is clear, however, is that the fashion industry - the world in general - will change even faster than before. And therein lies the opportunity for formats like Neonyt. The ten-year history shows in how many directions Neonyt has already developed, content focal points have been shifted and it has reinvented itself - this will also be the case in the future.

Mr. Schwenzfeier, in addition to your role as Director of Marketing Communications for Messe Frankfurt's textile exhibitions, you have also been Show Director of Neonyt since 2018. You have spoken to many exhibitors and visitors - which ideas or creations have particularly impressed you?

Thimo Schwenzfeier: I think it's not so much the individual innovations or creations of the exhibitors at our trade shows. And I deliberately choose the plural here. Because in my function as Director of Marketing Communications in the Textiles & Textile Technologies division of Messe Frankfurt, Neonyt is just one of "my" events. I think it's more the variety of fashion, technical and professional innovations that brands, labels, companies, start-ups and designers present every year. But if I really had to choose one innovation, it would probably be the vegan "Currywurst" sneakers made of red pepper and recycled PET bottles - the same label also offers shoes made of wood, stone, coffee and mushrooms or now even meteorite particles. It is impressive to experience every season anew of how creative the textile and fashion industry is.

Breaking new ground means being willing to make decisions, overcoming fears - and thus also having the courage to fail. Not every project can succeed. In retrospect, about which entrepreneurial decision by Messe Frankfurt are you particularly glad, that you made?

Olaf Schmidt: Clearly the decision to create Neonyt. To establish our own trade show format for fashion, sustainability and innovation and to integrate the freedom and lifestyle, which entail this topic, into our event. After more than a decade, we may be saying goodbye to Berlin in 2021, but not to our community and our spirit. Together we look back on many fashionable seasons and great locations in the capital: starting in the Hotel Adlon Kempinski to the Ewerk, the Postbahnhof, the Kronprinzenpalais, the Funkhaus and the Kraftwerk to the last physical event in Tempelhof. With the turn of the year and in the setting of Frankfurt Fashion Week, Neonyt is about to move to the metropolis by the Main. In Frankfurt, worlds collide: Skyscrapers and 19th-century villas. Architectural sins and masterpieces. Business and middle class. Red-light district and luxury boulevard. Frankfurt Fashion Week sets new impulses in this area of conflict. And in the middle of all this is Neonyt. The signs are pointing to a new beginning - a restart for the entire fashion industry, together we are taking sustainability to the next level - the focus topics Applied Sustainability and Applied Digitization are creating a completely new Fashion Week ecosystem in the metropolis by the Main.

If everything works out, Neonyt can be held again as a face-to-face event for the first time in July 2021. What are your plans? What and who can visitors look forward to? And what backup is there for a worst-case scenario?

Thimo Schwenzfeier: Of course, due to the currently ongoing tense situation around Covid-19, it is difficult to make binding statements about the next physical event. However, we are cur rently expecting the situation to ease into the summer summer 2021 is therefore on the health of everyone - exhibitors, visitors, partners and employees of Neonyt. Messe Frankfurt has developed a concept that includes detailed hygienic measures: Hygiene, distance and fresh air supply are important factors, which we coordinate with the responsible authorities in Frankfurt and those in charge of Frankfurt Fashion Week. In due course, the Neonyt community will receive advice and recommendations for the trade show attendance and participation, that comply with current regulations. We have not yet thought about a concrete backup for a worst-case scenario, as we are currently anticipating a physical B2B event - but the last two seasons have shown, should it not be possible to hold the Neonyt face-to-face, that we are quite well positioned with the digital Neonyt on Air and could certainly adapt the format for another summer event. We regularly exchange ideas with all market participants and try to get a sense of opinions and wishes from our community through surveys. Wait and see, one might say - in the end, we also have to act according to what the current health situation allows and what decisions are made by politicians.

The Interview was conducted by Ines Chucholowius,

Managing Partner, Textination GmbH