AI helps chemists develop tougher plastics

Researchers created polymers that are more resistant to tearing by incorporating stress-responsive molecules identified by a machine-learning model.

A new strategy for strengthening polymer materials could lead to more durable plastics and cut down on plastic waste, according to researchers at MIT and Duke University.

Using machine learning, the researchers identified crosslinker molecules that can be added to polymer materials, allowing them to withstand more force before tearing. These crosslinkers belong to a class of molecules known as mechanophores, which change their shape or other properties in response to mechanical force.

“These molecules can be useful for making polymers that would be stronger in response to force. You apply some stress to them, and rather than cracking or breaking, you instead see something that has higher resilience,” says Heather Kulik, the Lammot du Pont Professor of Chemical Engineering at MIT, who is also a professor of chemistry and the senior author of the study.

The crosslinkers that the researchers identified in this study are iron-containing compounds known as ferrocenes, which until now had not been broadly explored for their potential as mechanophores. Experimentally evaluating a single mechanophore can take weeks, but the researchers showed that they could use a machine-learning model to dramatically speed up this process.

MIT postdoc Ilia Kevlishvili is the lead author of the open-access paper, which appeared Friday in ACS Central Science. Other authors include Jafer Vakil, a Duke graduate student; David Kastner and Xiao Huang, both MIT graduate students; and Stephen Craig, a professor of chemistry at Duke.

The weakest link

Mechanophores are molecules that respond to force in unique ways, typically by changing their color, structure, or other properties. In the new study, the MIT and Duke team wanted to investigate whether they could be used to help make polymers more resilient to damage.

The new work builds on a 2023 study from Craig and Jeremiah Johnson, the A. Thomas Guertin Professor of Chemistry at MIT, and their colleagues. In that work, the researchers found that, surprisingly, incorporating weak crosslinkers into a polymer network can make the overall material stronger. When materials with these weak crosslinkers are stretched to the breaking point, any cracks propagating through the material try to avoid the stronger bonds and go through the weaker bonds instead. This means the crack has to break more bonds than it would if all of the bonds were the same strength.

To find new ways to exploit that phenomenon, Craig and Kulik joined forces to try to identify mechanophores that could be used as weak crosslinkers.

“We had this new mechanistic insight and opportunity, but it came with a big challenge: Of all possible compositions of matter, how do we zero in on the ones with the greatest potential?” Craig says. “Full credit to Heather and Ilia for both identifying this challenge and devising an approach to meet it.”

Discovering and characterizing mechanophores is a difficult task that requires either time-consuming experiments or computationally intense simulations of molecular interactions. Most of the known mechanophores are organic compounds, such as cyclobutane, which was used as a crosslinker in the 2023 study.

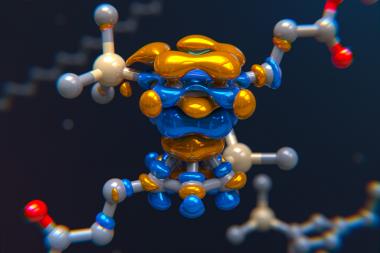

In the new study, the researchers wanted to focus on molecules known as ferrocenes, which are believed to hold potential as mechanophores. Ferrocenes are organometallic compounds that have an iron atom sandwiched between two carbon-containing rings. Those rings can have different chemical groups added to them, which alter their chemical and mechanical properties.

Many ferrocenes are used as pharmaceuticals or catalysts, and a handful are known to be good mechanophores, but most have not been evaluated for that use. Experimental tests on a single potential mechanophore can take several weeks, and computational simulations, while faster, still take a couple of days. Evaluating thousands of candidates using these strategies is a daunting task.

Realizing that a machine-learning approach could dramatically speed up the characterization of these molecules, the MIT and Duke team decided to use a neural network to identify ferrocenes that could be promising mechanophores.

They began with information from a database known as the Cambridge Structural Database, which contains the structures of 5,000 different ferrocenes that have already been synthesized.

“We knew that we didn’t have to worry about the question of synthesizability, at least from the perspective of the mechanophore itself. This allowed us to pick a really large space to explore with a lot of chemical diversity, that also would be synthetically realizable,” Kevlishvili says.

First, the researchers performed computational simulations for about 400 of these compounds, allowing them to calculate how much force is necessary to pull atoms apart within each molecule. For this application, they were looking for molecules that would break apart quickly, as these weak links could make polymer materials more resistant to tearing.

Then they used this data, along with information on the structure of each compound, to train a machine-learning model. This model was able to predict the force needed to activate the mechanophore, which in turn influences resistance to tearing, for the remaining 4,500 compounds in the database, plus an additional 7,000 compounds that are similar to those in the database but have some atoms rearranged.

The researchers discovered two main features that seemed likely to increase tear resistance. One was interactions between the chemical groups that are attached to the ferrocene rings. Additionally, the presence of large, bulky molecules attached to both rings of the ferrocene made the molecule more likely to break apart in response to applied forces.

While the first of these features was not surprising, the second trait was not something a chemist would have predicted beforehand, and could not have been detected without AI, the researchers say. “This was something truly surprising,” Kulik says.

Tougher plastics

Once the researchers identified about 100 promising candidates, Craig’s lab at Duke synthesized a polymer material incorporating one of them, known as m-TMS-Fc. Within the material, m-TMS-Fc acts as a crosslinker, connecting the polymer strands that make up polyacrylate, a type of plastic.

By applying force to each polymer until it tore, the researchers found that the weak m-TMS-Fc linker produced a strong, tear-resistant polymer. This polymer turned out to be about four times tougher than polymers made with standard ferrocene as the crosslinker.

“That really has big implications because if we think of all the plastics that we use and all the plastic waste accumulation, if you make materials tougher, that means their lifetime will be longer. They will be usable for a longer period of time, which could reduce plastic production in the long term,” Kevlishvili says.

The researchers now hope to use their machine-learning approach to identify mechanophores with other desirable properties, such as the ability to change color or become catalytically active in response to force. Such materials could be used as stress sensors or switchable catalysts, and they could also be useful for biomedical applications such as drug delivery.

In those studies, the researchers plan to focus on ferrocenes and other metal-containing mechanophores that have already been synthesized but whose properties are not fully understood.

“Transition metal mechanophores are relatively underexplored, and they’re probably a little bit more challenging to make,” Kulik says. “This computational workflow can be broadly used to enlarge the space of mechanophores that people have studied.”

The research was funded by the National Science Foundation Center for the Chemistry of Molecularly Optimized Networks (MONET).

Source: Anne Trafton | MIT News