San Francisco Fire Department Adopts Non PFAS Turnout Gear

The San Francisco Fire Department (SFFD) has become the largest department in the United States to transition its entire fleet to non-PFAS turnout gear. The gear was purchased in part through a $2.35 million Assistance to Firefighters Grant (AFG) from FEMA and matching funds from the department, amid growing momentum around identifying PFAS alternatives in firefighting gear.

The department worked with textile innovator Milliken & Company and gear manufacturer Fire-Dex to fulfill the order, whose first shipment was delivered this month. The department plans to receive 1,100 sets of non-PFAS turnout gear, one set for every frontline suppression member, by December 31, 2025.

“As the San Francisco Fire Department continues to lead in innovation, we remain steadfast in our commitment to protecting the health and safety of our members. Firefighting is inherently dangerous, and our personnel deserve access to the most modern, protective, and safest turnout gear available. Transitioning to PFAS-free equipment is a critical step in advancing our mission: safeguarding the public by ensuring our firefighters remain healthy and able to serve at their highest capacity,” said SFFD Fire Chief Dean Crispen.

Chief Crispen added, “This distribution represents more than new gear, it reflects a strong, coordinated effort among the Fire Department, our elected leaders, SF Firefighters IAFF Local 798, and the SF Firefighters Cancer Prevention Foundation. Milliken and Fire-Dex rose to this challenge, demonstrating what is possible when partners are united by a shared purpose. This collaboration is what the residents and visitors of San Francisco expect and deserve. A protected workforce is the foundation of a protected community. By investing in the well-being of our firefighters, we strengthen the health, resilience, and safety of San Francisco as a whole.”

The transition follows an ordinance passed in May 2024 making San Francisco the first city in the country to ban the use of PFAS chemicals in its firefighters’ turnout gear. With a June 30, 2026 deadline to make the switch, department officials worked efficiently to procure and test potential solutions, selecting the final gear well ahead of the deadline.

The selected gear went through rigorous performance and safety testing, including a 90-day wear trial with 50 firefighters going through live fire training at the San Francisco Division of Training burn rooms. The gear is UL certified and meets the NFPA 1971-2018 and 1971-2025 standards.

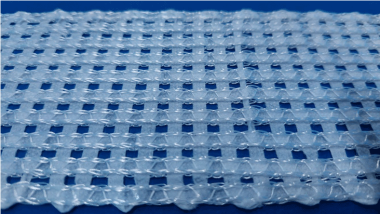

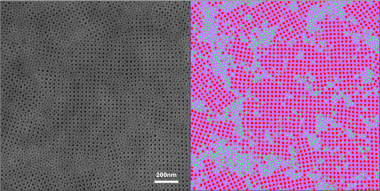

While non-fluorinated fabrics have existed for turnout gear outer shells and thermal liners, moisture barrier alternatives remained a key technical challenge. The introduction of Milliken Assure™ — North America’s first non-PFAS, non-halogenated flame-resistant moisture barrier — in October 2024 made it possible for Fire-Dex to provide SFFD with a solution that met all requirements.

“A non-PFAS moisture barrier was the missing piece for departments wanting to move away from fluorinated chemicals,” said Marcio Manique, SVP and Managing Director of Milliken’s apparel business. “With Assure™, we refused to trade one hazard for another. It meets the strictest performance standards without adding weight or compromising breathability – giving firefighters exactly what they asked for.”

SFFD worked with MES Life Safety to order the garments from Fire-Dex and size each firefighter individually for their new equipment. Milliken and Fire-Dex have maintained a decade of strategic collaboration that delivers fire service innovation and advancement through U.S. research and manufacturing.

“Fire-Dex is honored to supply the San Francisco Fire Department with AeroFlex turnout gear featuring a non-fluorinated moisture barrier,” said Jeff Koledo, Fire-Dex Vice President of Sales. “We’re grateful to work alongside Milliken and MES in delivering this solution. Our goal has always been to provide fire departments across the country with options that meet their needs — and ultimately ensure they have the essential protection required to keep their communities safe.”

San Francisco encompasses 49 square miles and is the fourth largest city in the state of California. The SFFD is the 10th largest fire department in the United States, serving an estimated 1.5 million people. With 45 stations, firefighters respond to an average of 180,000 annual emergency calls.

Milliken