Freudenberg to return to Wire Düsseldorf in 2026

Freudenberg Performance Materials (Freudenberg) is returning to the Wire trade fair in Düsseldorf, Germany, after a gap of several years. The experts from one of the world's leading suppliers of technical textiles are looking forward to presenting their comprehensive range of high-performance tapes for power, data, and specialty cables to visitors at the trade fair and discussing solutions from April 13-17.

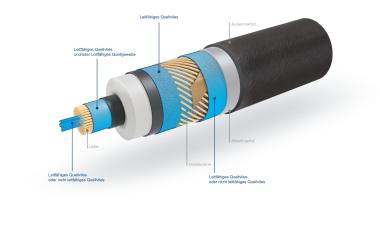

Freudenberg will showcase its high-performance cable tapes for all kinds of applications, including power, data, fiber optic, telecom, and special cables. Its cable tape product range for medium (MV) and high (HVDC and HVAC) voltage cables includes semi-conductive and non-conductive water-blocking tapes, binding tapes, bedding tapes, separation tapes, and special developments. These tapes are critical for protecting and maintaining the structural integrity of cables, in particular thanks to their outstanding swelling performance and conductivity. For submarine cables, Freudenberg offers tapes with exceptional water-blocking capabilities that are specifically designed to react instantly upon contact with water, swell into the fine spaces inside the submarine cable, and seal against moisture.

“Freudenberg is a globally preferred partner of cable manufacturers as regards the development, manufacture and supply of high-performance tapes for the most demanding power and data transmission applications. By returning to Wire in Düsseldorf, we are strengthening our ties within the industry and demonstrating our commitment to supporting cable manufacturers in meeting today's and tomorrow's energy and digital challenges” says Jochen Bialek, Head of Global Sales Cable & Electro.

Freudenberg Performance Materials