Trützschler introduces new Comber Machine

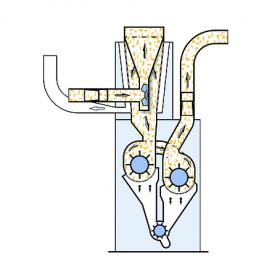

Comber machines from Trützschler are already trusted by customers across the textiles industry and around the globe. The TCO 21 is the latest addition to their portfolio and was built to boost productivity, ensure quality and support increased automation.

High productivity and raw material savings

One of the key benefits of the TCO 21 is its advanced processing speed. This next-generation combing machine is able to produce at a rate of up to 600 nips per minute. the TCO 21 can also be coordinated with Trützschler’s JUMBO CANS (Ø 1.200 mm). They not only reduce yarn defects due to fewer piecings which leads to quality improvements, but also offer a higher efficiency because of their larger dimensions. This, for example, has positive effects on the number of necessary cans and can transports – and results in lower personnel costs.

Excellent yarn quality

The TCO 21 comes with COUNT MONITORING as standard. This feature makes it possible for the machine operator to define limits for count variations via an easy-to-use display. Trützschler’s DISC MONITOR system of sensors measures the count continuously, and the machine alerts the operator and switches off if the limit is exceeded. In addition, the COUNT MONITORING function also includes spectrogram analysis.

Customers can further strengthen their focus on quality by choosing to add the COUNT CONTROL function to the TCO 21. It is managed via the same easy-to-use display, and offers automatic sliver count measurement, as well as spectrogram analysis. It also automatically regulates the main draft during production to balance count variations and ensure the desired sliver count. This feature is particularly attractive for customers who manufacture blends of cotton and synthetic, as it can also be used to avoid variations in the overall yarn composition.

Automatic optimization

The TCO 21 joins the TCO 12 from Trützschler as an combing machine that offers automatic PIECING OPTIMIZER technology, and that finds the right piecing setting without a single laboratory test, because of two functions: First by adjusting the piecing time in the combing cycle (timing function). Whereas the resetting of the detaching point (piecing time) is usually a very time-consuming task, it now takes only a few minutes and is performed automatically at a push on a button. Second the customer is helped to select specific detaching curve types (curve function) for their unique requirements.

Easy operation

The TCO 21 is simple to operate and maintain. The SMART TOUCH display is fast and intuitive, and a Radio-Frequency Identification (RFID) sensor quickly identifies each user and adapts the information on the display to their individual needs. The multi-colored T-LED display provides visual indications of the machine’s status or quality parameters over large distances which enables the operator recognizing them at a glance in the entire spinning mill. The TCO 21 is built with original Trützschler electronics that ensure high performance and durability: Their intelligent cooling system, that has already proven itself in the draw frame TD 10, contributes to a longer service life by reducing the operating temperature of electronic power components. Even if components have to be replaced at some point, the customer can keep their spare parts inventory small, because they can switch also electronics spare parts flexibly between different machine types, e.g. cards and draw frames. The option to add an automatic greasing function completes the easy operation of the TCO 21.

Trützschler