Dr. Stefan König neuer CEO der Optima Unternehmensgruppe

Die Optima Unternehmensgruppe hat Dr. Stefan König zum neuen Chief Executive Officer (CEO) ernannt. Er übernimmt die Rolle von Hans Bühler, geschäftsführender Gesellschafter, der in die Position des Chairman wechselt.

Im April 2024 hat Hans Bühler den Titel des Chief Executive Officer (CEO) an Dr. Stefan König übergeben, der bereits seit 2021 als Geschäftsführer im Unternehmen tätig ist. König bringt über 25 Jahre Erfahrung aus verschiedenen Bereichen des Maschinenbaus mit. Zuletzt war er als CEO der ehemaligen Bosch Packaging Technology GmbH tätig.

Bühler selbst, der über 35 Jahren Sprecher der Geschäftsführung war, wird sich in der vierköpfigen Geschäftsführung als Chairman auf Zukunftsthemen, strategische Entscheidungen und den Gesellschafterkreis fokussieren.

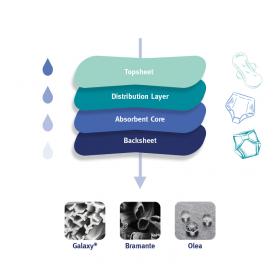

König wird als CEO die Geschäftsführung koordinieren sowie Initia-tiven und Beschlüsse zur Zielerreichung treffen und durchführen. Er teilt sich mit Dr. Johannes-Thomas Grobe die Verantwortung für die vier Geschäftseinheiten Pharma, Consumer, Nonwovens und Life Science inklusive des Bereichs Wasserstoffwirtschaft, sowie die unternehmensübergreifenden Themen Digitalisierung, Nachhaltig-keit und Marketing. Die Zentraleinheiten wie Personal und Finanzen werden von Jan Glass gesteuert. Er wird im Laufe des Jahres sein Amt an seinen designierten Nachfolger Marco Beyl übergeben.

OPTIMA packaging group GmbH