Trevira CS at Heimtextil 2019

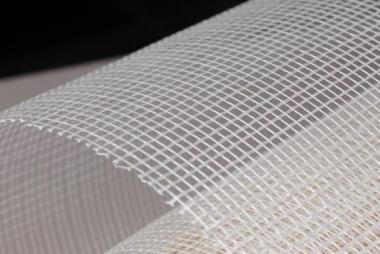

At this year’s Heimtextil from 8-11 January 2019 in Frankfurt, Trevira GmbH presented a new Trevira CS joint stand on an impressively huge scale under the motto “Textile Values”. Its fair stand concept, scaled up for 2019, attracted a large number of visitors. Together with 26 top Trevira CS customers, Trevira told the story of the entire textiles value chain across a 2,200+ msq site. Visitors were taken on a journey that started with the basics – fibre production and yarn manufacture – before moving on to the dyeing, weaving and warp and weft knitting stages and ultimately to the end of the journey, the textile editing.

Trevira GmbH’s CEO Klaus Holz said, “I think we have once again “upgraded” our presence at Heimtextil. If I say this I’m not only talking about size and number of participants in our stand, but rather about value. Including all kinds of Trevira CS partners from yarn producers to fabric manufacturers and textile editors, our stand was reflecting the entire textile value chain.”

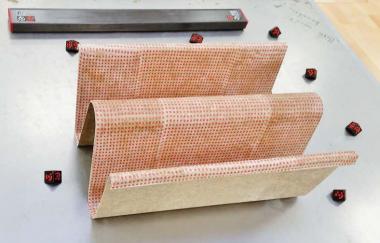

The highlight of the stand was Trevira’s new trend show for the contract market, “Trends in Contract by Trevira CS”. The show gave visitors, especially (interior) designers and decorators, an opportunity to find out more about innovative textiles and colour trends on the home and contract market.

Head of Marketing Anke Vollenbröker said, “We are extremely pleased that our trend show met with such great interest, and it was fantastic to see so many interior designers participating in our trend gallery tours. The trend area proved to be a source of inspiration for numerous visitors and demonstrated the expertise of our Trevira CS partners when it comes to outstanding design.”

Trevira GmbH