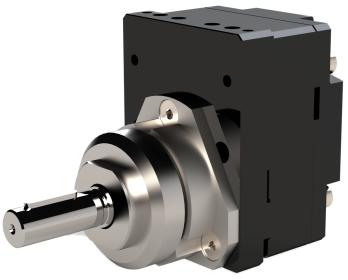

Barmag at PaintExpo – Focus on paint metering pumps

At this year's PaintExpo in Karlsruhe (April 14–17), Barmag will present an optimized design of its paint metering pump. It impresses with its low weight, increased productivity, and extended service life. Specially developed for compact robot arms, the pump enables high-precision and economical paint application – ideal for industries such as automotive, aerospace, and renewable energies.

Paint application is one of the most demanding production steps. In order to meet increasing requirements for service life and quality, highly efficient systems are needed that create resistant surfaces. Oerlikon Barmag has been manufacturing gear metering pumps since 1985, which enable reliable and economical paint application thanks to maximum metering accuracy.

The new pump sets standards in industrial coating technology. It impresses with maximum metering accuracy and minimal pulsation – for uniform and precise paint application. The flushing system is optimized for the shortest possible flushing times, while its low weight facilitates integration into compact robot arms.

A particular highlight is that the pump combines all these advantages with high cost-effectiveness. "Our new paint metering pump combines precision and cost-efficiency in a single product. This enables us to create real added value for our customers in a wide range of industries," explains Thorsten Wagener, Sales Manager responsible for the Pumps division.

Oerlikon Barmag