ACI: Launch of Bio-Based Textiles in Clothing: Europe 2025 Conference

ACI announces the launch of its conference, Bio-Based Textiles in Clothing: Europe 2025.

Following in the footsteps of the successful Biobased Coatings Europe series with latest edition bringing together over 160 senior level attendees in Valencia in June 2024, this inaugural conference will explore the latest advancements in sustainable clothing made from renewable resources.

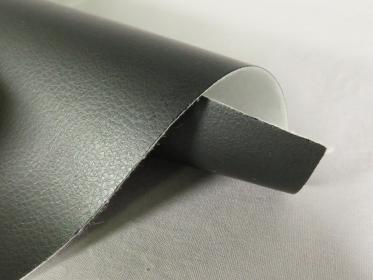

Taking place on the 15th & 16th January 2025 in Helsinki, Finland, just after the EU's pivotal Textile EPR Directive comes into force, this event will provide a deep dive into the world of bio-based textiles, examining how plants, microbes, and other novel organic feedstock are being revolutionised into sustainable, stylish garments.

ACI (Europe)