Flos and B&B Italia partner with “Casa Italia Paris 2024”

Flos and B&B Italia, furniture brands of Made in Italy design, take part in the Casa Italia Paris 2024 project, the hospitality house that will host the athletes and guests during the XXXIII Olympic Games, to be held in the French capital from 26 July to 11 August 2024.

Along with other design brands and contemporary Italian artists, the two companies participate for the first time at Casa Italia Paris 2024 showcasing their most iconic creations, both classic and contemporary, in the venue’s indoor and outdoor spaces, taking guests on a spectacular and evocative journey that epitomizes Italian elegance and beauty.

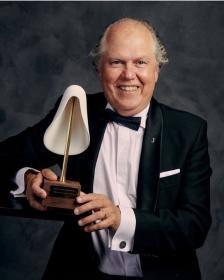

As Official Partner of Casa Italia Paris 2024, B&B Italia is furnishing the living, lounge and outdoor areas with some of its most recognisable products that combine unique design, quality, comfort and function as well as sustainability, an increasingly crucial element intrinsic to furniture designed to last over time. The UP Series by Gaetano Pesce, the Camaleonda sofa and Le Bambole seating by Mario Bellini, the Planck tables by Piero Lissoni, and the Allure O’ table and Flair O’ chairs by Monica Armani will furnish Casa Italia, highlighting a dialogue with the context through the choice of distinctive shapes, colours and materials.

The ongoing dialogue created by the brand’s products continues through to the outdoor lounge areas, where Casa Italia’s green spaces are dotted with products from the B&B Italia Outdoor collection, the brand’s outdoor furniture line launched in 2007. The Ribes sofas by Antonio Citterio, the Crinoline chairs by Patricia Urquiola and the Borea tables by Piero Lissoni will welcome athletes and guests creating stylish aesthetic synergies with the Le Pré Catelan gardens.

Flos has worked at the lighting project for Casa Italia Paris 2024 as Official Supplier, with the aim of making light a precious element for highlighting the works of art and the objects that enrich the setup of the Italian hospitality house, so that the exhibition and its narrative itinerary can be enjoyed both during daytime and nighttime hours. Light is used to shape the space in such a way as to create visual hierarchies among the superb items on display, without forgetting the ambient lighting needed for the celebratory events that will take place in the venue. The Flos lighting display includes some of the brand’s most recognisable suspension creations, such as cocoon models Taraxacum and Viscontea by Achille and Pier Giacomo Castiglioni and Zeppelin by Marcel Wanders. These interact with more recent and timeless collections, such as Glo-Ball by Jasper Morrison, Arrangements by Michael Anastassiades, IC and Captain Flint floor lamps, also by Anastassiades, and Bellhop Floor by Barber Osgerby.

For the exterior green spaces, Flos has chosen stylish outdoor floor lamps that create a harmonious dialogue with the surrounding architecture. These include Captain Flint Outdoor and IC Outdoor, designed by Michael Anastassiades, featuring bases in precious materials such as Tuscan imperial travertine and volcanic stone from the slopes of Mount Etna. Finally, Flos Architectural, the brand’s professional lighting division for large-scale projects, has equipped Casa Italia with innovative tech solutions that include The Tracking Magnet, an ingenious patented system with magnetic fastening LED lights in spot or linear versions for functional, efficient lighting that is also comfortable and non-invasive.

B&B Italia S.p.A.