The Future Of Stretch: New Project To Validate Bio-based And Recycled Elastane

Stretching Circularity is a collaborative project initiated by Fashion for Good dedicated to accelerating the adoption of lower-impact elastane alternatives that are compatible with circular textile systems. By validating bio-based and recycled elastane solutions through pilot-scale testing and demonstrator garments, the initiative aims to remove one of the most significant technical barriers to a circular textile economy.

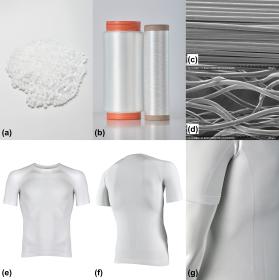

Present in approximately 80% of all clothing, elastane is a material added in varying concentrations (typically from 1–5% by weight in cotton or wool garments to up to 20% in polyester or polyamide garments) to provide stretch and comfort. This fossil-based material creates two critical sustainability challenges:

- First, it contributes to carbon emissions and non-renewable resource consumption across the industry.

- Second (and more critically for circularity), even minimal concentrations of elastane act as a “contaminant” in textile recycling feedstocks, compromising fibre-to-fibre recycling of high-volume fibres like polyester and cotton. This effectively blocks circularity for the vast majority of clothing, leaving the industry with limited options beyond downcycling or landfill.

Stretching Circularity is a project initiated by Fashion for Good which tackles this challenge through two key workstreams. One workstream focuses on testing next-generation elastane materials made from alternative inputs, including bio-based materials and other feedstocks. This phase includes the creation of “demonstrator” garments, specifically a technical t-shirt (with 10% elastane) and a non-technical t-shirt (with 2% elastane). The other focuses on testing regenerated elastane made through emerging recycling innovations. Both workstreams follow a pilot-scale validation approach to generate comparable data on performance, impact, economical feasibility and scalability.

Driving this work is a powerful coalition of industry stakeholders representing the entire value chain. The consortium includes Fashion for Good partners Levi Strauss & Co (Beyond Yoga), On, Paradise Textiles, Positive Materials, and Reformation, with Ralph Lauren Corporation as an Advisor. Supported by ecosystem experts like Materiom and the Ellen MacArthur Foundation, the group will support knowledge sharing across the consortium to identify gaps and generate comparative data to de-risk the adoption of these circular solutions for the wider industry. Stretching Circularity operates under a structured due diligence and validation framework to assess if alternative materials are not just conceptually sound but also meet the performance standards of conventional elastane.

“Lower-impact elastane solutions exist, but they lack the pilot-scale validation brands need to scale them confidently,” Katrin Ley, Fashion for Good Managing Director. “This initiative seeks to provide that missing data, turning a well-known recycling “contaminant” into a functional component of a circular supply chain.”

“Elastane is one of the most overlooked blockers to true circularity in fashion: it’s everywhere and yet there is a significant challenge to recovering it at scale. Stretching Circularity is about tackling that problem at the root and proving that lower-impact stretch materials and new recycling pathways can meet real performance and design standards.” Carrie Freiman Parry, Senior Director of Sustainability at Reformation

Fashion for Good