Mahlo at Febratex 2024: Advancements in straightening technology and process control

Mahlo GmbH + Co. KG announces its participation in the Febratex trade show from August 20 to 23, 2024. The event will take place in Blumenau, Brazil, a hub for textile and garment production.

The company will present its latest advancements in straightening technology and process control. The booth will be jointly hosted by Mahlo’s sales agency MBR Textile and Christian Matthias, the head of Mahlo’s application department. They will be available to provide in-depth knowledge and demonstrations of Mahlo's solutions.

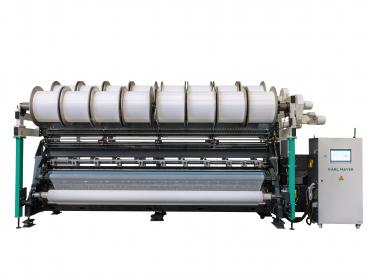

Mahlo’s technology addresses the critical needs of textile manufacturers, ensuring high-quality production with minimized distortion and optimized processes. The company’s automatic straightening system guarantees thread-

straight fabric across various applications, thanks to its modular design that can be tailored to individual production environments. Additionally, Mahlo offers several process control systems designed to optimize stenter frame operations by measuring and controlling parameters such as dwell time, thread density, and residual moisture. These systems help manufacturers improve textile quality, save raw materials, and reduce energy costs.

Mahlo GmbH & Co. KG