Fraunhofer IZM: High-Tech Fashion – art and science for the clothes of tomorrow

For most people, the word "fashion" evokes thoughts of cuts, colors and patterns - but why not of live evaluations of vital functions or training sessions for rehabilitation patients? Up to now, products of the fashion industry have been largely analogous. The project Re-FREAM, however, was created to design smart clothes in the digital area. Here, researchers and artists work side by side, developing innovative and sustainable ideas and implementation options for the fashion industry, while simultaneously providing impulses for user-oriented synergies between textiles and technology.

The writer Maxim Gorki summed up the connection between two social spheres that were long believed to be irreconcilable: "Just as science is the intellect of the world, art is its soul". In the project Re-FREAM they are connected because fashion is not limited to the decision of the external, it is directly afflicted with sociological, technological and ecological world views. It is less and less sufficient to present only the beautiful, because the dark sides of the fashion industry must also be uncovered and countered with sustainable production cycles and fair working conditions. It is precisely this rethinking and redesigning of processes, production methods, but also of functionality and traditions in the world of fashion that is part of the Re-FREAM project.

The aim is to create an interaction between fashion, design, science and urban manufacturing in order to combine creative visions with sustainable technological solutions. In teams, artists and scientists developed projects together and then presented their innovative aesthetics at the virtual Ars Electronica Festival 2020.

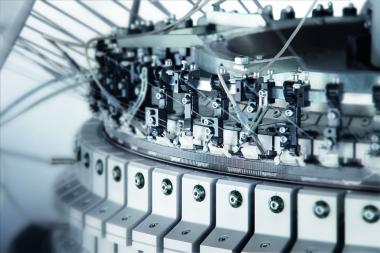

The cooperation with Fraunhofer IZM's scientists opens up entirely new technological possibilities for artists: Microelectronics not only serves as a fashion accessory but is also brings new functions to clothing. With the help of integration technologies, clothing can be integrated into networks and textile-integrated sensor technology can be used, which opens up perspectives of wearable applications in the field of e-health.

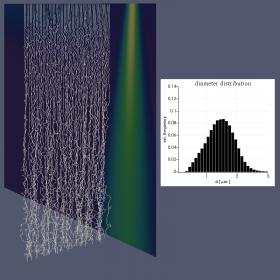

One difficulty that Fraunhofer researchers are facing is the electronic contact points between electronics and textiles, because these must be manufacturable on an industrial scale and function reliably under typical textile mechanical stress and washing without any loss of performance. The electronic modules are a further challenge. At Fraunhofer IZM, the electronic components are miniaturized to such an extent that they do not stand out in the garment. The connecting conductor tracks are finally laminated or embroidered onto the fabrics.

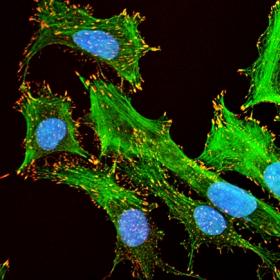

Each sub-project in Re-FREAM is a unique joint effort, a fact that reflects the versatility of the cooperation partners. The Italian designer Giulia Tomasello, for example, wants to reveal taboos around female health in her project "Alma" and realize a monitoring of the vaginal flora. The team consisting of designers, an anthropologist and Fraunhofer researchers is developing underwear with an integrated pH sensor, designed to enable a non-invasive diagnosis of bacterial vaginosis and fungal diseases in everyday life and prevent serious inflammation.

In the gusset of the underwear, the reusable biosensor collects data and transmits them to a module measuring approximately 1 cm². Thanks to a modular design, the microcontroller can be easily removed from the textiles. The textile sensor, too, can be removed from the underwear. In addition to the technological solution, aesthetic requirements are another main focus. Other potential applications would be the monitoring of abnormal uterine bleeding as well as menopause. "Through close cooperation with the artists, we have gained very special insights into the user's perspective, and they in turn into that of application-oriented technologies. We have always challenged each other and have now found a solution that combines medical technology, wearables and a circular production method to empower women," says Max Marwede, who provided technical support for "Alma" at Fraunhofer IZM.

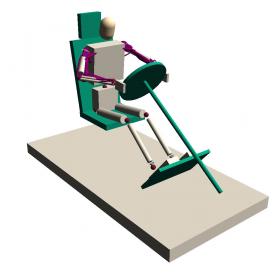

In the "Connextyle" project around designer and product developer Jessica Smarsch, the team also focuses on developing user-oriented garments: The tops, which are equipped with textile printed circuit boards and laminated EMG sensors, measure muscle activity and thus optimize rehabilitation processes for patients. An app provides visual feedback from the collected data, generates reports on the healing process and makes it easier for therapists to adapt the measures ideally.

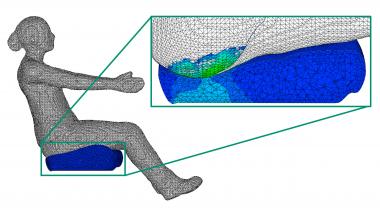

Soft Robotics are the key point in the "Lovewear" project, because here inclusive underwear was developed, which is intended to help people with physical limitations in particular to explore their own intimacy and develop a greater awareness of their own body. Through interaction with a connected pillow, which functions as an interface, compressed air inserts are activated in the lace fabric. Instead of the commonly used silicon-based materials, Soft Robotics are made of textiles and thermoplastic materials. The researchers thus avoid the long curing process of silicone-based approaches and enable faster and more cost-effective mass production with available textile machines.

Particularly challenging and at the same time fruitful is the collaboration in creating sustainable and circular production designs in fashion. Ecological principles are taken into account at the design stage, minimizing negative environmental impacts throughout the product life cycle. This includes the reliability of the component contacts, the length of time the sensors adhere to the textile, the choice of materials and the modular design for reuse of the microcontrollers. However, the teams do not create individual pieces - they want to show that the path to high-tech fashion can also be an environmentally friendly one. They also worked on circular business models that fit the sustainable mission of the projects.

Thus Fraunhofer IZM’s expertise in the fields of e-textiles and circular design represents a considerable added value in the Re-FREAM project. With further investigations on suitable conductive materials, the researchers are currently developing sensory textiles and textile-suitable interconnection technologies. They are also working on thermoplastic substrates that can be integrated into almost any textile.

Re-FREAM is part of the STARTS (Science + Technology + Arts) program, which is funded as an initiative of the European Commission within the Horizon 2020 research and innovation program.

Fraunhofer Institute for Reliability and Microintegration IZM