TEXTILE INDUSTRY IN PAKISTAN MUST MODERNIZE

- The cultivation of cotton is to be expanded

Pakistan's textile industry has lost competitiveness. Investments in new textile technology are necessary. Exports of German machinery increase.

The textile industry is Pakistan's most important industrial sector. In Pakistan's fiscal year 2017/18 (July 1st 2017 to June 30th 2018), the textile industry accounted for 8.5 percent of gross domestic product. The sector accounted for about a quarter of the total industrial value added. It is by far the country's most important export sector. Textile exports accounted for 58 percent of total exports in 2017/18.

However, the international competitiveness of the sector is currently declining. This trend should turn around. Prime Minister Imran Khan met with representatives of the textile industry at the end of January 2019. Economic policy aims to expand and modernize the textile industry. Production costs are to be reduced and productivity increased. In addition, quality improvements, production expansions and higher added value are necessary.

The textile industry's value chain begins with around 1,300 companies that are ginning, process and bale raw cotton. In addition to the demand for cotton, the demand for synthetic fibers is also increasing, although there are only three manufacturers of polyester fibers in Pakistan to date.

The number of spinning mills is estimated at 517 in 2017 and the number of weaving mills at 124 large and 425 medium-sized and small mills. Ten large and 625 medium-sized and small companies process fabrics. Towels were produced by about 400 companies, knitted fabrics by 2,500 companies. Clothing made of woven fabrics was supplied by 50 large factories and 2,500 medium-sized and small factories.

Export transactions stagnate

Pakistan's textile exports grew by 8.7 percent to USD 13.5 billion in 2017/18. This level was already reached in 2013/14 and 2014/15. Textile exports in the first seven months of fiscal year 2018/19 (July 18th to January 19th) increased slightly by 1.2 percent year-on-year to US$ 7.8 billion.

| Products | 2013/14 | 2014/15 | 2015/16 | 2016/17 | 2017/18 |

| Total | 13,733 | 13,471 | 12,447 | 12,452 | 13,530 |

| .Cotton yarn | 1,997 | 1,849 | 1,265 | 1,244 | 1,372 |

| .Cotton fabrics | 2,770 | 2,453 | 2,214 | 2,136 | 2,204 |

| .Towels | 767 | 797 | 803 | 801 | 797 |

| .Bed linen | 2,138 | 2,103 | 2,020 | 2,136 | 2,261 |

| .Clothing | 1,906 | 2,095 | 2,195 | 2,319 | 2,579 |

| .Knitted goods | 2,294 | 2,406 | 2,364 | 2,361 | 2,720 |

| .Other products | 1,858 | 1,767 | 1,586 | 1,452 | 1,597 |

*) Fiscal years (July to June)

Sources: All Pakistan Textile Mills Association (APTMA); Pakistan Bureau of Statistics; Textile Commissioner's Organization

The All Pakistan Textile Mills Association (APTMA) aims to increase exports to USD 28 billion by 2023/24. This requires consistent state support and long-term export promotion, according to the association.

The leading foreign customer is the USA. Other important customers include the United Kingdom, Germany and Spain. In 2017 and 2018, Germany imported textile materials and goods worth EUR 1 billion from Pakistan.

Machine imports still declining

Imports of textile machinery in 2013/14 amounted still to USD 599 million. In the following three years it was USD 449 million (2014/15), USD 462 million (2015/16) and USD 557 million (2016/17). Imports are not currently showing an upward trend despite the need for modernization. According to the statistics authority, they fell by 42 per cent to USD 325 million in 2017/18. There are still no signs of a recovery in 2018/19 either.

| HS-Positions | 2014 | 2015 | 2016 | 2017 |

| 84.45 Spinning machines etc. | 230 | 162 | 162 | 246 |

| 84.46 Looms | 84 | 73 | 107 | 90 |

| 84.47 Knitting machines etc. | 70 | 84 | 65 | 75 |

| 84.48 Auxiliary machinery for HS headings 84.44 to 84.47 |

85 | 70 | 77 | 82 |

Sources: Pakistan Bureau of Statistics, UN Comtrade

Business trip to the fifth largest customer of German spinning technology

According to calculations by the German Engineering Federation (VDMA), German textile machinery exports to Pakistan increased to EUR 53 million in 2017. The previous year's figure was EUR 48 million, EUR 39 million of which was attributable to spinning machines.

A business trip of German companies from the textile machinery and accessories sectors will take place to Karachi and Lahore from November 11th to 15th 2019. The Federal Ministry of Economics and Energy will promote and the company SBS Systems for Business Solution will organize the trip (contact: Thomas Nytsch, e-mail: thomasnytsch@sbs-business.com).

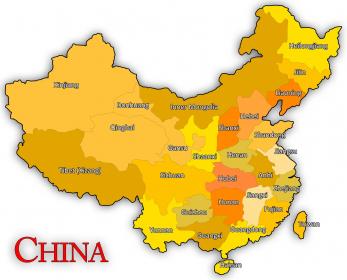

Cotton production to be strongly increased

The local cotton production is the base of the textile industry. After India, China and the USA, Pakistan is the fourth largest cotton producer, followed by Brazil and Uzbekistan. Without an increase in local crop yields, the growth of the textile industry is limited. Increased imports of cotton would further reduce the industry's struggling international competitiveness.

In an international comparison, the country is one of the cotton producers with the lowest yields per hectare. Australia, Turkey, China and Brazil form the leading group with about 1,600 to 1,700 kilograms per hectare. Pakistan only reaches 600 to 800 kilograms.

| Year | Cultivation area (in hectares) |

Production (in 1,000 bales) 1) |

Yield per hectare (in kilograms) |

| 2013/14 | 2,086 | 12,769 | 774 |

| 2014/15 | 2,961 | 13,960 | 802 |

| 2015/16 | 2,902 | 9,917 | 582 |

| 2016/17 | 2,489 | 10,671 | 730 |

| 2017/18 | 2,699 | 11,935 | 752 |

| 2018/19 2) | 2,500 | 11,000 | 748 |

1) one bale = 170 kilograms, 2) Forecast

Source: Pakistan Bureau of Statistics; research by Germany Trade & Invest

The government has set a production target of around 15 million bales for 2019/20. APTMA believes an increase to 20 million bales is possible by 2023/24. The association assumes that there will be about 2,800 hectares of cultivated land and an increase in yields per hectare to 1,200 kilograms.

Problems with the supply of cotton

Baumwolle wird vor allem in den Provinzen Punjab und Sindh angebaut. Die Baumwollproduktion erreichte 2014/15 noch rund 14 Millionen Ballen. Die Ernte fiel 2015/16 auf unter 10 Millionen und lag 2017/18 bei 12 Millionen Ballen. Die Produktion ist 2018/19 wieder gesunken, ein Wert von etwa 11 Millionen Ballen wird prognostiziert. Als Gründe werden unter anderem Wassermangel, eine schlechte Qualität der Pflanzenschutzmittel und minderwertiges Saatgut genannt. Zudem sei die finanzielle und regulatorische Unterstützung der Regierung unzureichend, so Branchenvertreter.

The local supply could therefore no longer cover the annual cotton demand of the textile industry of 15 to 16 million bales in recent years. Textile manufacturers therefore imported cotton mainly from India and China, about 3 million to 4 million bales a year. However, imports from India have been stopped since February 2019. The background to this is the political tensions and recent military conflicts between the two states.

Robert Espey, Germany Trade & Invest www.gtai.de