Medical Fibers with "Inner Values"

Medical products such as ointments or syringes reach their limits when it comes to delivering medication locally – and above all in a controlled manner over a longer period of time. Empa researchers are therefore developing polymer fibers that can deliver active ingredients precisely over the long term. These "liquid core fibers" contain drugs inside and can be processed into medical textiles.

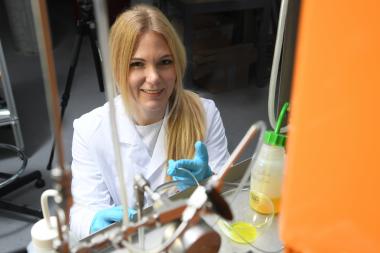

Treating a wound or an inflammation directly where it occurs has clear advantages: The active ingredient reaches its target immediately, and there are no negative side effects on uninvolved parts of the body. However, conventional local administration methods reach their limits when it comes to precisely dosing active ingredients over a longer period of time. As soon as an ointment leaves the tube or the injection fluid flows out of the syringe, it is almost impossible to control the amount of active ingredient. Edith Perret from Empa's Advanced Fibers laboratory in St. Gallen is therefore developing medical fibers with very special "inner values": The polymer fibers enclose a liquid core with therapeutic ingredients. The aim: medical products with special capabilities, e.g. surgical suture material, wound dressings and textile implants that can administer painkillers, antibiotics or insulin precisely over a longer period of time. Another aim is to achieve individual, patient-specific dosage of the drug in the sense of personalized medicine.

Biocompatible and tailor-made

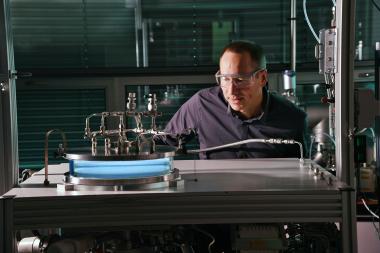

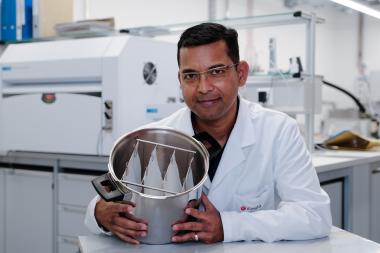

A decisive factor that turns a conventional textile fiber into a medical product is the material of the fiber sheath. The team chose polycaprolactone (PCL), a biocompatible and biodegradable polymer that is already being used successfully in the medical field. The fiber sheath encloses the valuable substance, such as a painkiller or an antibacterial drug, and releases it over time. Using a unique pilot plant, the researchers produced PCL fibers with a continuous liquid core by means of melt spinning. In initial lab tests, stable and flexible liquid-core fibers were produced. What's more, the Empa team had already successfully demonstrated, together with a Swiss industrial partner, that this process not only works in the lab but also on an industrial scale.

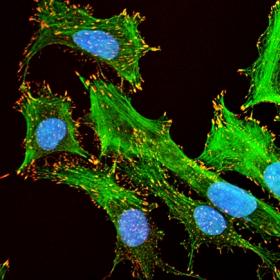

The parameters according to which the medical fibers release an enclosed agent were first investigated using fluorescent model substances and then with various drugs. "Small molecules such as the painkiller ibuprofen move gradually through the structure of the outer sheath," says Edith Perret. Larger molecules, on the other hand, are released at the two ends of the fibers.

Precisely controllable and effective in the long term

“Thanks to a variety of parameters, the properties of the medical fibers can be precisely controlled," explains the Empa researcher. After extensive analyses using fluorescence spectroscopy, X-ray technology and electron microscopy, the researchers were able to demonstrate, for instance, the influence of the sheath thickness and crystal structure of the sheath material on the release rate of the drugs from the liquid core fibers.

Depending on the active ingredient, the manufacturing process can also be adapted: Active ingredients that are insensitive to high temperatures during melt spinning can be integrated directly into the core of the fibers in a continuous process. For temperature-sensitive drugs, on the other hand, the team was able to optimize the process so that a placeholder initially fills the liquid core, which is replaced later on by the sensitive active ingredient.

One of the advantages of liquid core fibers is the ability to release the active ingredient from a reservoir over a longer period of time. This opens up a wide range of possible applications. With diameters of 50 to 200 micrometers, the fibers are large enough to be woven or knitted into robust textiles, for example. However, the medical fibers could also be guided inside the body to deliver hormones such as insulin, says Perret. Another advantage: Fibers that have released their medication can be refilled. The range of active ingredients that can be administered easily, conveniently and precisely using liquid core fibers is large. In addition to painkillers, anti-inflammatory drugs, antibiotics and even lifestyle preparations are conceivable.

In a next step, the researchers want to equip surgical suture material with antimicrobial properties. The new process will be used to fill various liquid core materials with antibiotics in order to suture tissue during an operation in such a way that wound germs have no chance of causing an infection. Empa researcher Perret is also convinced that future collaboration with clinical partners will form the basis for further innovative clinical applications.

Aiming for clinical partnerships

Advancing a new technology? Identifying innovative applications? Empa researcher Edith Perret is looking for interested clinicians who recognize the potential of drug delivery via liquid core fibers and want to become active in this field.

Dr. Andrea Six, EMPA