Spring Edition of Intertextile Shanghai Home Textiles returns in March 2019

- The Spring Edition of Intertextile Shanghai Home Textiles will be held from 12 – 14 March 2019, serving as a perfect occasion for the industry to start the sourcing season and to tap into the promising finished products market in China.

- Bedding products as strong driving force for home textiles market

Bedding products account for half of home textiles sales in China. Thanks to the rising number of middle class citizens and a steady increase in new marriages every year, there is a growing demand for bedding products. According to the National Bureau of Statistics, the total income of those bedding enterprises above a designated size* reached USD 12.3 billion in the period between January and September 2018, while their domestic sales amassed USD 8.3 billion, representing a year-on-year increase of 6.2%.

Spring is traditionally regarded as the start of a new year in China and Intertextile Shanghai Home Textiles has been facilitating industry players to capture the market potential during the peak sourcing season for home textile finished products. The 2018 Spring Edition was sought after by the industry, and more than 20,000 buyers from 68 countries and regions came to source. It also offered valuable opportunities for exhibitors to tap into the China market. “It is one of the important platforms for us to launch products for the year as many suppliers and brand buyers are looking for new items during this prime sourcing period. We also expect the demand for quality finished products to keep growing due to the rising living standard,” Mr Gao Qi, District Manager of Sunvim Co Ltd commented after their participation in 2018.

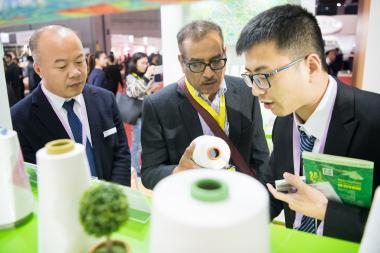

With such positive market prospects, around 200 suppliers from China and around the world will showcase their products including bedding & towelling, carpets & rugs, table & kitchen linen, home textile technics, textile design and more in March 2019.

Messe Frankfurt