Hong Kong Polytechnic University develops intelligent activewear

The Paris 2024 Summer Olympic Games are just around the corner and a global sports frenzy is underway. However, intense summer workouts often lead to sportswear absorbing excessive sweat, becoming clingy and cumbersome, causing discomfort and potentially impacting performance. A research team from the School of Fashion and Textiles at The Hong Kong Polytechnic University (PolyU) has developed the iActive™ sportswear range which features a root-like liquid transport system and a skin-like active perspiration dissipater and utilises nature-inspired, anti-heat textile fabrics to expedite sweat removal, effectively reducing the weight and stickiness of activewear caused by sweat accumulation during exercise.

The human body has millions of sweat glands that are vital for regulating body temperature by dissipating sweat for evaporation to cool the skin’s surface. With unabating greenhouse gas emissions, the number of very hot days annually is expected to increase significantly. This will lead to elevated energy consumption and increased sweating during physical activity and outdoor labour. Even when wearing highly breathable clothes with good sweat-wicking properties, individuals may still experience discomfort due to excessive sweat accumulation.

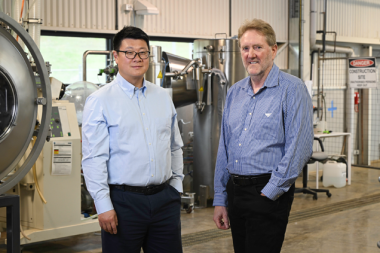

A research team led by Dr SHOU Dahua, Limin Endowed Young Scholar in Advanced Textiles Technologies and Associate Professor of the School of Fashion and Textiles at PolyU, has invented the iActive™, intelligent, electrically activated sportswear with a nature-inspired active perspiration function.

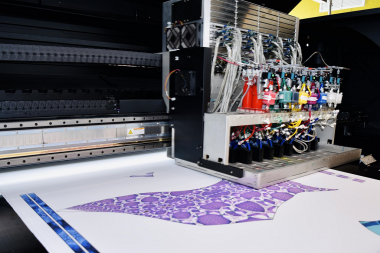

Its nature-inspired technologies, including low-voltage-driven artificial “sweat glands” created by skin-like anti-heat textile fabrics and a root-like branching liquid transport system that aligns with the body’s sweat map, can actively and programmably remove sweat to a perspiration dissipater at the lower region of the sportswear. The all-textile sweat dissipater is compact and operates at a safe output voltage of approximately 5-9V, and its battery is easy to detach from the clothing, making it convenient for users to repeatedly wash the clothing by hand or in a washing machine to maintain hygiene. When the human body’s sweat rate is low, iActive™ can still be used independently without the battery.

Based on the optimised wettability pattern and gradient, the research team utilises a skin-like textile fabric to transport sweat one-way quickly and dissipate it from the inside to the outside. This feature reduces the stickiness and weight of clothing, improves breathability and ensures the garments remain dry and comfortable to wear. Experimental findings indicate that iActive™ creates a breathable and dry skin microclimate by dissipating sweat at a rate that is three times faster than the maximum human sweating rate. This innovation can also prevent discomfort from coldness and moisture after a workout. In comparison to traditional fabrics, the textile materials in iActive™ are 60% lighter and 50% less clingy when soaked, providing the wearer with all-round comfort and enabling sports enthusiasts and athletes to perform at their best.

Furthermore, a mobile app further aids personalised sweat management by wirelessly adjusting the sweat level of iActive™. This innovation is versatile and can be seamlessly integrated into a variety of textile materials to facilitate sustainable mass production. Beyond sportswear, iActive™ is also well-suited to protective clothing and workwear for individuals engaged in prolonged, high-intensity physical labour and outdoor occupations, including healthcare professionals, construction workers, firefighters, law enforcement officers and others, thereby significantly enhancing their work performance.

Dr Shou Dahua stated, “The extreme weather and high temperatures resulting from global warming have elevated the importance of heatstroke prevention and cooling measures on a global scale. Drawing on the vivid phenomena of thermal insulation and directed liquid flow in nature, we aim to foster innovation and sustainable advancement in garment manufacturing by inventing intelligent clothing and materials to address global challenges. We seek to harness the power of technology to infuse fresh perspectives into the traditional clothing industry, thereby enhancing its competitiveness.”

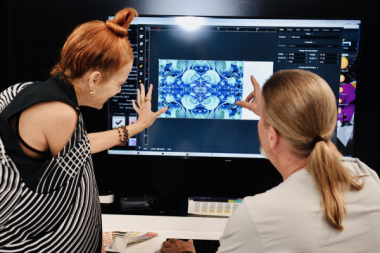

His research team has also developed a premium fabric named Omni-Cool-Dry™, drawing inspiration from volcano dwelling beetles. This fabric not only provides ultra-fast sweat dissipation and ensures all-day comfort with its dry and breathable features under dynamic thermal conditions, but also reflects solar radiation and emits body heat into the cold universe, enabling passive cooling. The team is working hard to leverage the benefits of both inventions to further enhance the sweat-dissipating and cooling capability of iActive™ sportswear.

Dr Shou Dahua, a core member of the PolyU Research Institute for Intelligent Wearable Systems and the Research Centre of Textiles for Future Fashion, has recently been bestowed with the 2023 Distinguished Achievement Award by The Fiber Society for his outstanding contributions to the fields of personal thermal and moisture management, intelligent wearables and soft robotics. The accolade is presented annually to an individual researcher worldwide. He has also received international innovation awards, including consecutive TechConnect Global Innovation Awards in 2021 and 2022. Moreover, his research papers have been published in various internationally renowned academic journals including Science Advances, PNAS, Advanced Functional Materials, and Advanced Energy Materials. Dr Shou will be chairing The Fiber Society Spring 2025 Conference at PolyU.

Hong Kong Polytechnic University

Hong Kong Polytechnic University