The AVK presents its awards virtually for the first time

The AVK – Industrievereinigung Verstärkte Kunststoffe e.V. – has once again announced the winners of its prestigious Innovation Awards. Decided by an expert jury, the awards recognise and honour sustainable innovations in three categories: “Innovative Products/Applications”, “Innovative Processes” and “Research and Science”.

Overview of all the winners in the three categories:

Category “Innovative Products/Applications”

1st Place: “Directly-cooled electric motor with integral lightweight housing made of fibre reinforced polymers - DEmiL” – developed by the Fraunhofer Institute for Chemical Technology ICT, Pfinztal, Germany, in partnership with the Karlsruhe Institute of Technology and Sumitomo Bakelite Co., Ltd.*

2nd Place: “Intrinsically Reprocessable, Repairable and Recyclable (3R) thermoset composites for more Competitive and Sustainable Industries” – developed by cidetec, Donostia-San Sebastian, Spain*

3rd Place: “Fireproof composite metal hybrid structure – LEO® fire protection sandwich with integrated Hyconnect steel-glass hybrid connector” – developed by SAERTEX GmbH & Co. KG and Hyconnect GmbH.*

Category “Innovative Processes”

1st Place: “Robotised Injection Moulding (ROBIN)” – developed by Robin, Dresden with the Institute for Lightweight Engineering and Polymer Technology at the TU Dresden*

2nd Place: “Omega stringer from the roll” – developed by the German Aerospace Center, Braunschweig*

3rd Place: “Hybrid die-casting – manufacturing of intrinsic CFRP-aluminium composite structures in aluminium high-pressure die-casting” – developed by Faserinstitut Bremen e. V. with Fraunhofer IFAM, Bremen*

Category “Research and Science”:

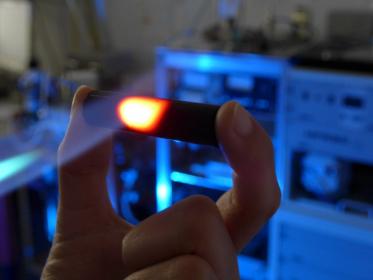

1st Place: “New high-temperature resistant UP resins and toughening agents” – developed by Münster University of Applied Sciences with BASF SE Global New Business Development, Leibniz Institute for Polymer Research e. V., Saertex multicom GmbH*

2nd Place: “Scientific basis for the industrial application of the thermoplastic resin transfer moulding (T-RTM) process” – developed by Fraunhofer Institute for Chemical Technology ICT, Pfinztal*

3rd Place: “The material- and energy-efficient production of turbine struts by the integrative combination of thermoset fibre reinforced materials” – developed by the Institute of Polymer Technology, University of Erlangen-Nuremberg with the German Aerospace Center, Gubesch Group, Schmidt WFT, Siebenwurst, Raschig.

Award ceremony on the Internet for the first time

For the first time, due to the Covid-19 pandemic, the award ceremony took place as an online event on 12 November 2020. Many of the award winners’ innovations will be presented again in this year’s AVK Innovation Award brochure. This will be available online: https://www.avk-tv.de/innovationaward.php

*Please see attached document for more information.

AVK – Industrievereinigung Verstärkte Kunststoffe e.V