Monforts: New Stenter line installed at Curt Bauer

Monforts' new Montex 8500 stenter line was recently installed at Curt Bauer’s plant in Aue in Germany.

Curt Bauer has been in continuous operation for 150 years, beginning as a weaving mill in Aue in the Ore Mountains region of Saxony back in 1882. Today, with 120 employees, the company has an annual production of 2.2 million metres of fabric and specialises in three key fields – home textiles, special damask fabrics for West African garments and technical textiles.

A first Montex stenter was installed by Monforts at the Aue plant in 2003 and an older machine from a third party supplier was also still in operation prior to the latest upgrade.

“The replacement of our older existing stenter, which was installed in 1985, was long overdue,” explains Gert Bauer. “It had a maximum working width of 2.2 metres and we were looking to both increase productivity and reduce energy requirements.”

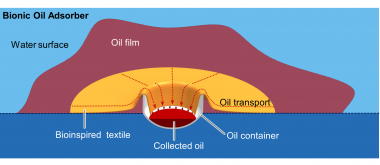

As a consequence, the company opted for a new Montex 8500 line with a working width of 3.2 metres equipped with the MonforClean heat recovery and exhaust air purification system. The Montex stenter remains unmatched in terms of its robustness and long service life and with MonforClean technology, the waste heat from the drying process is used to pre-heat the drying air. This results in a radical reduction in the conventional heat supply required, compared to full gas and thermal oil heating. Overall energy savings of up to 40% can now be achieved compared to conventional stenters.

The first challenge at the Aue plant was how to fit the significantly larger machine into the available space without restricting the area required for docking operations.

The special multi-level configuration that Monforts designers and Curt Bauer’s team devised in order to meet these requirements involved raising all of the line’s drying zones – with a combined length of over 28 metres – on scaffolding platforms, to enable the ground floor space below them to continue to be fully utilised.

The next challenge involved configuring the MonforClean system without having to make any costly changes to the roofing structure. This, Gert Bauer observes, demanded “millimetre precision”.

With the new line now fully operational, the savings it is providing have yet to be fully calculated.

A. Monforts Textilmaschinen GmbH & Co. KG