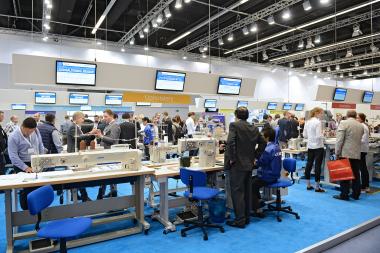

TEXTILE AND CLOTHING INDUSTRY IN ASIA: GTAI CHECKING THE SECTOR

Every day, GTAI experts observe and analyze the development of the most important German export industries on the world markets. Here you will find summarized information on the textile and clothing industry in Asian markets.

GTAI Industry Check - Vietnam

Textile and clothing industry: Vietnam needs more than sewing

The textile and clothing industry is one of the most important pillars of the Vietnamese industry and accounted for around 6 percent of total exports in 2017 with exports amounting to USD 26 billion. For 2018, the industry is aiming for growth of 7 to 8 percent and exports are expected to rise to over USD 33 billion. In order to comply with the rules of origin of the free trade agreements concluded by Vietnam, the country must achieve a higher added value. Domestic companies such as the Vinatex Group or Garco10, but also foreign companies are increasingly investing in technical innovations and expanding processes such as spinning, weaving and dyeing upstream of pure sewing. In addition, the first companies are beginning to automate their production processes.

GTAI Industry Check - Uzbekistan

Textile and clothing industry: Investments of more than USD 2 billion planned

The industry program for 2017 to 2020 lists around 130 projects with a total value of USD 2 billion. About half of the planned investments are to be

accounted for foreign commitments. The aim is to double the annual output of finished textile products during this period. With an annual production of more than 3 million tons of raw cotton, Uzbekistan is one of the world's largest producers of the white gold. A second industry programme foresees the implementation of five projects for the production of raw silk, silk wadding and silk fabrics and finished silk products between 2018 and 2021. The minimum investments required are estimated at USD 26 million.

GTAI Industry Check – Myanmar

Textile and clothing industry: Export strength through low wages

The lifting of sanctions by the EU and the US has noticeably revived the investment climate in the sector, especially as this was linked to the reactivation of the EU's GSP import status (Generalized System of Preferences). Most investors came from China, Hong Kong, Taiwan or South Korea, and Western brands such as GAP, H & M, Primark or Marks & Spencer were also included. Currently, about 400,000 workers are employed in almost 400 factories, mostly geared to CMP (cut-make-pack), including 171 foreign investors and 22 joint ventures. According to the Myanmar Garment Entrepreneurs Association, exports are expected to have increased by 40 percent to over USD 3 billion by 2017. For the first time the largest customer was the European Union, primarily Germany, ahead of Japan and South Korea.

GTAI Industry Check – Georgian Republic

Textile and clothing industry: Several expansion projects planned

The apparel industry produces garments for up to USD 70 million annually. The main products manufactured are international brands for export. Several new projects in the industry are in preparation. For example, the Turkish jeans manufacturer Baykanlar Textil plans to build a factory for the production of brand jeans in Ozurgeti by the end of 2018. A total of USD 15 million will be invested in the project. The Romanian company MGMtex, a subsidiary of the Swiss company Ottorose, is planning to start production of branded clothing in Kutaisi in cooperation with a local partner. The investments for the first and second project phases amount to more than USD 1.5 million. For the procurement of equipment, the company benefits from subsidies from the state program Produce in Georgia.

GTAI Industry Check - Turkmenistan

Textile and Clothing Industry: Investments of around 300 million US dollars planned

The textile and clothing industry represents 20 percent of Turkmenistan's industrial production and 30 percent of its manufacturing industry. A good USD 300 million will be invested in 2018 to 2020/21. The project list includes the construction of a large textile complex for the annual processing of up to 5,000 tons of fine-fibred cotton into semi-finished and finished products. Start March 2021; contractor: Cotam Enterprises Ltd, British Virgin Islands/Turkey) and a factory for the annual production of 6,000 tons of cotton yarn (2019/20, Hilli yol), the modernization of a textile factory (Daschogus), a cotton spinning mill (Tachtabasar) and a factory for medical wadding and cosmetic cotton (Ashgabat; 2018/2019 each). The potential of medical textiles, cotton fabrics, man-made fibers and the processing of wool and cocoons is still little used.

GTAI Industry Check – Azerbaijan

Textile and clothing industry: Light industry business park attracts investors

Azerbaijan launched several projects to revive the industry (output in 2017: USD 100 million). An industrial park for light industry has been under construction in Mingachevir since autumn 2016. Nine new factories are planned for cotton, acrylic and woolen yarn, clothing, hosiery and leather shoes. The project is worth up to USD 150 million. The first factory for the annual production of 20,000 tons of yarn is under construction. Under the umbrella organization for the Azerkhalcha carpet weaving mill founded in 2016, ten further smaller factories will be put into operation in 2018. Gilan Textil Park, Sumqayit, wants to expand its exports of home textiles. In the medium term, the construction of a silk spinning mill with an annual capacity of 3,000 tons of yarn is also planned.

GTAI Industry Check - Armenia

Textile and clothing industry: interest from abroad increases

Rising exports of clothing to Russia and western markets lead to expect further investments in the textile and clothing industry in 2018. Italian investors are planning to build a large jersey factory in Kapan (Sjunik region). The company SASSTEX in Artik (Schirak region) invests in two factories for the production of fashion (ZARA brand) and workwear. The Egyptian Wassef Group is considering the production of cotton fabrics and products therefrom. Yerevan-based hosiery and children's apparel manufacturer Alex Textile will continue its USD 28 million investment program in 2018 to expand apparel and hosiery production at several sites in Armenia.

Germany Trade & Invest www.gtai.de