Cinte Techtextil China announces exhibitors for December Edition

From 7 – 9 December 2022, Cinte Techtextil China will welcome visitors sourcing solutions for 12 application areas of technical textiles and nonwovens at the National Exhibition and Convention Center in Shanghai.

A number of countries and regions are represented at the fair’s International Zone, with companies from Austria, Belgium, France, Germany, Hong Kong, Italy, the Netherlands, Spain, Sweden, Switzerland, Taiwan, and the US. Standout international exhibitors include:

- TESTEX, an international, independent Swiss institute which specialises in the testing and certification of textile and leather products. The organisation is a founding member and official representative of the OEKO-TEX® Association, and will present their certification services at the fairground.

- Cotton Council International (CCI) is a non-profit trade association that promotes US cotton fibre and manufactured cotton products, with their COTTON USA™ Mark. At this year’s fair they will showcase cotton spunlace fabric, wipes, kitchen tissues, facial masks, cosmetic removers, and more, with their products particularly applicable to Agrotech, Clothtech, Medtech, and Sporttech.

- Graf + Cie AG is a subsidiary of the Rieter Group, and a leading supplier of clothing for carding and combs for combing machines in the short- and long-staple spinning industry. This year, the Swiss company will showcase stationary flats, and metallic card clothing for roller cards.

- At the returning German Pavilion, buyers can source sought-after technical textiles and nonwovens that are renowned for their quality. The companies and expertise on display at this pavilion are endorsed by the Federal Republic of Germany, with several exhibitors highlighted below:

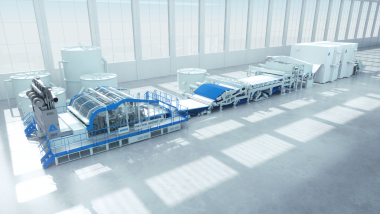

- Brückner Textile Technologies GmbH & Co KG has developed machinery for the textile industry since 1949. Today, the company offers complete line systems for the dry finishing of both woven and knitted fabric, as well as for technical textiles, glass fibres, and floor coverings.

- Perlon (Zhejiang) Co Ltd is part of a global group of companies that specialises in the manufacture of synthetic filaments, with factories in China, Germany, Poland, and the US. Their products have a diverse range of potential uses, largely categorised in the Agrotech and Indutech application areas.

- IBENA Textilwerke GmbH produces various functional fabrics for Protech. At the fair, the company will be showcasing insulative, flame retardant (FR) textiles for firefighting and search & rescue services. Developed with DuPont™ aramid material, their FR properties will not diminish after washing or repeated use.

This year’s fair also sees the return of the Taiwan Zone. With support from the Taiwan Nonwoven Fabrics Industry Association, the area will showcase a range of industry leading nonwoven products and services, by brands such as KNH Enterprise, Nan Liu Enterprise, Unique Pretty Ind, and Web-Pro Corporation.

As a world’s largest manufacturer of technical textiles, China is home to a vast array of companies responsible for innovative products. Some domestic exhibitors to look out for are:

- CTA Hi-Textiles Co Ltd, a high-tech enterprise controlled by China Textile Science Research Institute. In recent years, the company has developed several new textile composite materials, and their products are widely used in sectors such as national defence, policing and public security, medical protection, and engineering and manufacturing.

- Sateri is one of the world’s largest producers of viscose fibre, with an annual capacity of 1.8 million metric tonnes. At their mills, they make yarn and fibre products applicable to sectors such as beauty, hygiene and personal care, medical, wipes, and protective wear.

To help international buyers stay connected with the Chinese market, Match Plus, the fair’s online business matching platform, will support foreign buyers achieve their sourcing goals despite travel limitations. Further information on Match Plus will be available at a later stage.

The fair’s product categories cover 12 application areas, which comprehensively span a full range of potential uses in modern technical textiles and nonwovens. These categories also cover the entire industry, from upstream technology and raw materials providers to finished fabrics, chemicals and other solutions.

Cinte Techtextil China Technical Textiles Testex Cotton Council International Graf Brückner Perlon IBENA CTA Hi-Textiles Sateri

Messe Frankfurt (HK) Ltd