A circular school blazer

Vision and technology are the key ingredients of a ground-breaking school blazer that is showing how businesses can move to a circular textiles economy.

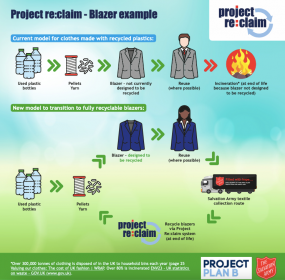

While many brands are grappling with the complexities of inevitable legislation and engrained business models, leading school uniform producer, David Luke, has launched a fully recyclable ‘circular’ school blazer that is designed to be recycled through Project Re:claim, the world’s first commercial-scale polyester recycling plant.

Project Re:claim is a joint venture between the UK’s largest charity textile collector, The Salvation Army, and leading circularity specialists Project Plan B. The plant opened in the UK in January 2024, and presents huge opportunities for brands to transition to textile-to-textile manufacturing models.

David Luke’s circular blazer has been introduced to the brand’s successful Eco-uniform range which has sold over 1.7 million Eco-blazers in the last decade. Up until 2023, David Luke’s Eco-blazer, like many recycled garments, has been made from recycled plastic bottles. But the company has been working with Tim Cross, CEO of Project Plan B and the Circular Textiles Foundation, to bring the 100% recyclable blazer to market.

Tim Cross said: “David Luke has grasped the opportunity to embed 100% recyclable and 100% recycled garments into their range, starting with the school blazer. We now have the technology to enable their blazers to be recycled without any separation of the garment, making it an efficient recycling process. The team at David Luke has worked tirelessly with their manufacturers to create a blazer that does not compromise on design or quality, and yet is much kinder to the environment.”

Every detail from the lining, buttons and zips to the inter-linings and adhesives, has been re-thought and re-designed to meet the demands of an everyday school blazer and to recycle the garment once it reaches its end-of-life. Up until now, when the blazers have eventually been handed down to siblings, or given to the local charity shop, there had been no end-of-life solution for polyester garments apart from incineration. Now, Project Re:claim can recycle the blazer to produce polyester pellets, which are then spun into yarn to be used for future David Luke circular blazers.

Cross continues: “David Luke has the vision to create a fully circular range, and we have the potential to supply recycled content. The possibilities are infinite in terms of the future of garment design and manufacturing.”

Kathryn Shuttleworth, Chief Executive of David Luke, said: “It is a natural next step for us to transition to a textile-to-textile model. We have been producing garments using recycled plastic bottles for 15 years, but we have always had an eye on developments in textile recycling and solutions for end-of-life garments.”

In 2020, David Luke was awarded the Queen’s award for Enterprise for Sustainable Development and in January 2023 the David Luke circular blazer achieved Circular Foundation Textile certification.

Shuttleworth added: “Our focus will always be on those essential ingredients for parents and children - style, durability and affordability. But we have a responsibility to change our business model to better protect children’s future and the environment. It has become our obsession to make uniforms that meet our customers’ demands. We are really excited about the future as we continue to develop our range.”

Majonne Frost, Head of Environment and Sustainability for Salvation Army Trading Company, said: “Our vision is to enable companies to produce uniforms, corporate wear, fashion garments and textile ranges using recycled polyester. We have the infrastructure to collect donations at scale and we now need companies to step up. This is an opportunity for companies to make a commitment to significantly reduce their environmental impact, and David Luke are showing us how that is possible.”