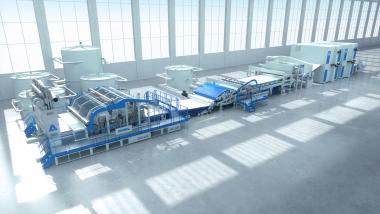

Hexcel’s HexPly® XF Surface Technology for Blade Surface Finishing Process

Hexcel announces its latest HexPly® XF surface technology that reduces shell manufacturing time within the wind blade surface finishing process. HexPly XF increases overall blade manufacturing efficiency by reducing time in the mold by up to two hours and by banishing surface defects that require rework before painting.

Hexcel’s HexPly XF surface technology has been formulated to address the limitations of current blade shell surfacing techniques whereby pinholes and other surface defects have to be repaired by hand to achieve the perfectly smooth surface required for painting.

HexPly XF surface technology introduces a new material format as the surface finishing layer, eliminating the need for a traditional in-mold gel coating process. HexPly® XF for infused rotor blades, is a lightweight non-woven semi-preg construction, comprising an epoxy resin matrix, that co-cures with standard epoxy infusion systems. The product has a successful track record in prepreg blades and has now been adapted for infusion processes.

Easy to handle and supplied in a ready to use roll form, HexPly XF can be quickly applied by hand or with semi-automated layup equipment. It features one self-adhesive, surface finishing side - indicated by a removable protective foil. This side of the prepreg is placed against a release agent treated mold surface. Once the material has been positioned, the lay-up of the blade shell structure can start immediately, and the laminate can be infused. After curing, the blade is de-molded with the manufacturer benefitting from a pinhole-free surface that needs minimal preparation before painting.

HexPly XF material is less than half the weight of a typical gel coat per square meter, reducing the overall weight of the blade. Additionally, the consistent areal weight and thickness of the prepreg film provide a completely uniform surface coating, ensuring blade weight distribution and balance are maintained, which is critical as rotor diameters continue to increase. With no need to handle or mix liquid chemicals as in the gel coat process, HexPly® XF also improves the health and safety working conditions on the shop floor.

The material has a shelf life of six weeks at ambient temperature, which also minimizes cold storage requirements and helps to reduce scrap.

100% Marketing