British textile machinery at Techtextil and Texprocess 2026

As global demand accelerates for lighter, stronger and more sustainable technical textiles, the machinery and testing technologies behind their manufacture are evolving at pace.

At the Techtextil and Texprocess exhibitions in Frankfurt this April, eight members of the British Textile Machinery Association (BTMA) will demonstrate how advanced engineering continues to shape the performance, precision and resource efficiency of advanced fibre and fabric production.

From the careful handling of ultra-high value yarns to the forensic inspection of finished fabrics, the exhibiting BTMA members collectively represent a complete chain of innovation across processing, monitoring and quality assurance.

“Techtextil provides an ideal global platform to demonstrate the depth and diversity of British textile machinery expertise,” says BTMA CEO Jason Kent. “From fibre extrusion and yarn handling to advanced inspection and testing, our members are delivering technologies that not only enhance performance but also support more sustainable and economically efficient manufacturing. We look forward to welcoming visitors to Frankfurt and to strengthening international partnerships across the technical textiles value chain.”

Airbond

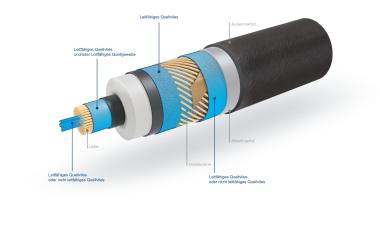

Airbond will highlight the latest advances in its pioneering pneumatic splicing technology. Invented by the company in the 1960s, pneumatic splicing has become indispensable not only in conventional textiles but also in the production of carbon and aramid components for aerospace, automotive and wind power applications. By intermingling individual filaments to create joints that are flatter and stronger than knots, the technology safeguards both performance and material value. Airbond’s latest patented splicers are 3D printed, making them lighter and stronger while enabling the processing of yarns up to 16,000 tex – far beyond the 1,200 tex capacity typical of most splicing systems. In sectors where technical yarns represent a major cost component, such resource efficiency delivers immediate economic and sustainability benefits.

Ascotex

Process stability at high speeds is equally dependent on precision yarn guidance. Ascotex will present its extensive portfolio of ceramic and hard-chromed yarn guides, tensioning devices, yarn break detectors, sensors, cutters and threading tools. In modern spinning and winding environments, where yarn velocities continue to rise and tolerances tighten, the surface over which a yarn travels becomes critical. Ascotex ceramic yarn guides, manufactured from high-grade technical ceramics, offer exceptional hardness and wear resistance, preserving geometry over extended production cycles. Their ultra-smooth surface finish minimises friction, heat build-up and abrasion, protecting filament integrity and ensuring uniform winding density and package formation. The result is enhanced downstream efficiency, reduced maintenance frequency and a quietly decisive contribution to overall production reliability.

Dent Instrumentation

Reliability in yarn monitoring is the focus of Dent Instrumentation. Its contactless yarn sensors have become a de facto industry standard, recognised for accuracy and durability and widely adopted under both Dent and OEM machine builder brands. Operating effectively at speeds from as low as 3 m/min to 8,000 m/min, with adaptable detection response tailored to individual requirements, the sensors are engineered for ‘fit and forget’ performance. Encapsulated in epoxy resin for protection against spin finish, oil, wax and water, and incorporating a unique optical compensation system to minimise cleaning, they deliver dependable performance across filament, elastomeric and staple fibre processes. Applications range from high speed POY and FDY winding and DTY processing with wrap detection, to ring, open end and friction spinning as well as creel and glass fibre twisting operations.

FET

Innovation in polymer processing will be showcased by Fibre Extrusion Technologies (FET). Working in close collaboration with customers, FET has developed more than 70 bespoke multifilament, monofilament and nonwoven polymer solutions for niche applications, supported by custom-designed extrusion, spunbond and meltblown systems. Its latest breakthrough addresses the manufacture of ultra high molecular weight polyethylene, a material prized for being up to ten times stronger than steel by weight and increasingly specified in medical implants and other demanding applications. Conventional UHMWPE production is typically large scale and complex, limiting development flexibility. FET’s industrialised lab and small scale gel spinning system, incorporating a patented batch solvent extraction process using supercritical CO2, enables the cost-effective production of smaller, bespoke quantities. As Managing Director Richard Slack explains, the system responds directly to demand from biomedical customers for tailored fibre sizes without the constraints of large-scale infrastructure.

James Heal

Testing and verification remain central to technical textile performance. James Heal will present the latest additions to its Performance Testing collection. The AirPro air permeability tester offers flexible standards compliance, comprehensive reporting and interchangeable test heads for woven, knitted and nonwoven applications. The HydroView hydrostatic head tester measures water penetration for materials used in medical, geotextile and nonwoven sectors as well as protective apparel and outdoor applications. With TruRain, water repellency testing has been redesigned to dramatically reduce wastewater and energy consumption. Meanwhile, the newly introduced Martindale Motion reimagines the industry-standard abrasion and pilling tester first developed by James Heal in the 1940s. The nine-station instrument allows independent operation of each head, enabling multiple tests to run simultaneously and automatically, including overnight, significantly improving laboratory productivity.

SDC Enterprises

Supporting standardised testing procedures, SDC Enterprises specialises in premium consumables engineered for BS, EN and ISO colour fastness and physical performance testing. Its range of colour fastness consumables, adjacent fabrics and verification materials ensures consistent, traceable and standards-compliant assessment of abrasion resistance, dimensional stability, light fastness and visual appearance. With full batch traceability, certificates of conformity and a global distribution network, SDC Enterprises underpins quality assurance programmes that protect both manufacturers and brand reputations.

Shelton Vision

Advanced fabric inspection technology will be demonstrated by Shelton Vision. Its latest WebSpector automated inspection system builds on established expertise in plain fabric monitoring with patent-pending image processing techniques capable of recognising and adapting to complex patterns, even where fabrics are subject to shear, stretch and local distortion. By compensating for real-time deformation and delivering a clean, analysable image at high speeds, WebSpector enables reliable fault detection across applications ranging from automotive interiors and one-piece woven airbags to performance wear, upholstery, sunscreen fabrics and carbon fibre composites.

VeriVide

Colour management, an increasingly critical parameter in technical textiles, will be the focus of VeriVide at Texprocess. Its systems are widely used in the assessment of automotive and aerospace interior materials, safety components and medical textiles. The latest DigiEye imaging system features 100 per cent LED illumination, integrated dust filtration and a fully enclosed camera, enhancing both accuracy and environmental performance. With software-integrated lighting controls, automated image capture and significantly expanded imaging and measurement areas, the new DigiEye streamlines high-volume colour assessment while eliminating the need for annual fluorescent lamp changes and extending light source longevity tenfold.

AWOL Media