Sappi at ITMA 2023

As a global provider of sustainable woodfibre products, Sappi will be showcasing its solutions for the garment industry under the theme “Fashion meets Forest” at ITMA 2023 – with sublimation papers and its dissolving wood pulp, used for the production of garment fibres under the “Verve” brand name.

How can the woodfibre industry support a more sustainable garments market? Sappi is eager to answer this question at the ITMA and has created a “knowledge trail” for visitors to explore under the motto “Fashion meets Forest”. Visitors to the stand can follow the journey from wood via cellulose and fibre to the finished yarn and the printed garment.

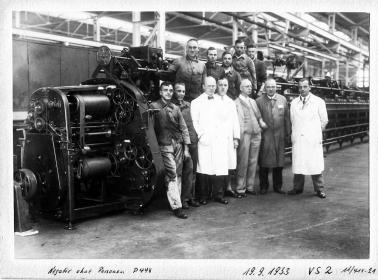

Sublimation papers: Expanded production capacity in Carmignano

Sappi’s Transjet sublimation papers stand for fast, uniform ink transfer and minimal ink consumption. As a premium supplier, Sappi is constantly striving to meet its customers’ needs. So, at this year’s ITMA, various sublimation papers with optimised qualitative properties will be on show.

Sappi maintains the high quality of its coated Transjet and uncoated Basejet sublimation papers by regularly investing in new, state-of-the-art technologies. At the end of April, a new warehouse has been inaugurated at the Carmignano mill in Italy. In the next month’s, Sappi will further invest in two new converting machines with a width of 1.9 meters and 3.2 meters as well as in a fully automated packaging line. All the investments will support the company’s vision of having a complete in-house solution for the sublimation industry, have a positive impact on CO2 emission, satisfy the increased demand of their customers as well as further improve lead times.

“Verve” dissolving wood pulp for high-quality textiles

Sappi will also be showcasing its dissolving pulp (DP) brand “Verve”. DP provides the feedstock raw material toward producing rayon fibres such as Lyocell and viscose and further into yarns and fabrics. Textiles produced from wood based cellulosic fibres are noted for their breathability, colour fastness, softness, drape, absorbency and biodegradability. In addition to the garment industry, dissolving pulp is also used in various household and pharmaceutical products.

Sappi Europe