Michelman counts on Textechno´s FIMATEST

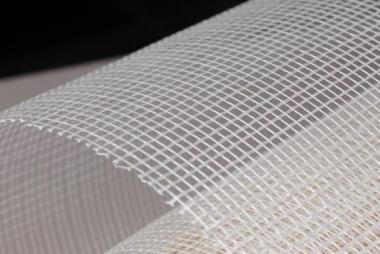

Michelman, a global developer and manufacturer of environmentally friendly advanced materials, including sizing for glass and carbon fiber, has invested in the FIMATEST adhesion measurement system to ensure their sizing solutions continue to contribute to enhanced performance of composite parts.

“As we continue our vision to be the interface expert, it is critical to have analytical equipment that can efficiently fine-tune our sizing to optimize adhesion properties. This is one of the key performance attributes we provide our customers, and the fact that the Textechno FIMATEST system works according to the fiber pull-out principle makes it extremely valuable”, explains Steve Bassetti, Michelman’s Global Marketing Director for Industrial Manufacturing. “We have utilized this equipment in our development lab for almost two years, and it is suited for any fiber-matrix combination we have developed. It has been helpful that Textechno developed these instruments because they are, and will continue to be, a great benefit to the entire Composites industry. We look forward to supporting Textechno in establishing more standardization for the Industry regarding fiber-matrix-adhesion and processing properties.“

Dr. Ulrich Mörschel, CEO of Textechno, added: “We are proud that Michelman, the industry’s leading interface expert, invested in our testing system.” Bassetti further elaborated on the system’s benefits: “For Michelman’s customers, this equipment has allowed for great collaboration, increased screening of sizing concepts, and a more robust and efficient product development process.”