Active Apparel Group: OEKO-TEX 100 Certified Water-Based Inks for Apparel Printing

As part of a broader initiative to reduce environmental impacts and keep ahead of evolving global chemical regulations, Active Apparel Group (AAG), manufacturer of performance apparel for the leisure/lifestyle and active market, is embracing water-based OEKO-TEX 100 Class 1 Standard Printing Inks in their manufacturing process.

Common and inexpensive inks used in the global manufacture of apparel contain a wide range of toxic chemicals, including phthalates, petroleum-based co-solvents, PVC, and other volatile organic compounds. AAG’s initiative to use OEKO-TEX approved, water-based inks creates benefits for factory workers, people living local to these factories, consumers, and everyone downstream.

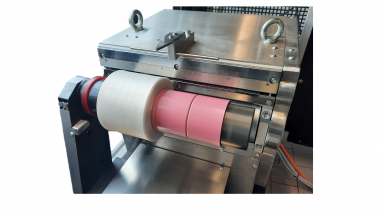

AAG offers a range of printing methods to address a variety of customer needs, including: digital printing, screen printing, and heat transfers for on-garment logos and care instructions. OEKO-TEX certified water-based inks are used for all of its digital printing and for the majority of its screen printing. These non-toxic water-based inks offer a socially and environmentally better alternative to the more commonly used Plastisol inks.

Making a sizable environmental impact, the printing service of AAG’s business is significant. Digital printing averages 25,000 meters per month with screen printing averaging 60,000 garments per month.

The use of water-based inks requires a skilled production team and training of employees is ongoing. AAG currently employs 30 people at its printing operations in Ningbo, China.

Active Apparel Group