Kornit Digital: 2020 Impact and Environmental, Social, and Governance Report released

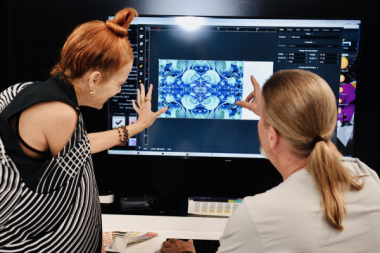

Kornit Digital Ltd., a worldwide market leader in digital textile production technologies, released its 2020 Impact and Environmental, Social, and Governance (“ESG”) Report. This inaugural report affirms Kornit’s commitment to achieving specific ESG goals. This includes the way Kornit conducts business, creates meaningful impact in local communities, and achieves environmental sustainability, in addition to how Kornit will continue to build a diverse and inclusive company culture, foster employee growth and development, and empower fair and safe labor practices globally.

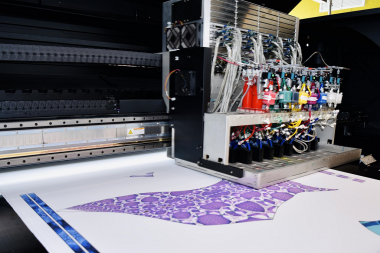

In addition to enabling eco-friendly production processes with technology and consumables that use less water, reduce waste, and minimize the carbon footprint, Kornit technology solutions enable sustainable production on demand, which eliminates overproduction of apparel and other textile goods. A 2021 Life Cycle Assessment conducted on two flagship products, the Kornit Atlas MAX and Kornit Presto S, demonstrated that relative to traditional analog processes, Kornit’s digital production systems used up to 95% less water and 94% less energy, and produced up to 83% less greenhouse gas (GHG) emissions for the Presto S system and up to 93% less water and 66% less energy, and produced up to 82% less greenhouse gas (GHG) emissions for the Atlas MAX system.

Based on this study, in addition to past sustainability performance results and strategic projections for business growth and market expansion, by 2026 Kornit Digital’s sustainable on-demand solutions are expected to enable the production of approximately 2.5 billion apparel items in a responsible manner to deliver:

- Zero overproduction: By moving the industry to on-demand manufacturing, Kornit will help eliminate the estimated 1.1 billion apparel items overproduced using traditional production methods, based on an industry average of 30% overproduction. This is about 1 apparel item for each and every person living in Europe and North America – saved.

- Zero water waste: In addition to eliminating overstocks, Kornit-enabled production on demand will support saving an estimated 4.3 trillion liters (1.1 trillion gallons) of water. This is the estimated amount of drinking water needed for the entire U.S. population for 11 years.

- Reduced CO2 emissions: By enabling sustainable on-demand production, consuming less energy, and generating less waste, Kornit will prevent an estimated 17.2 billion kilograms (37.9 billion pounds) of greenhouse gas emissions, compared to traditional manufacturing methods. This is equivalent to the estimated amount of carbon dioxide emitted from circumnavigating the entire planet with a car nearly 2,400 times.

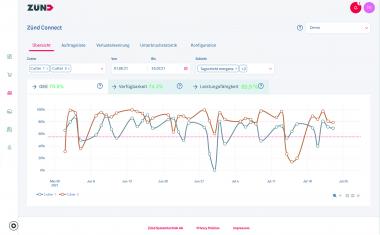

Furthermore, the report outlines Kornit’s commitment to achieving KPIs that address waste, chemicals, GHG emissions, energy, product development, employee training, diversity and inclusion, and the company’s supply chain.

pr4u