Industry veteran, Chris Govier joins Kornit Digital as Managing Director, Europe

Govier plans to scale the organization and take customer focus to the next level to drive growth

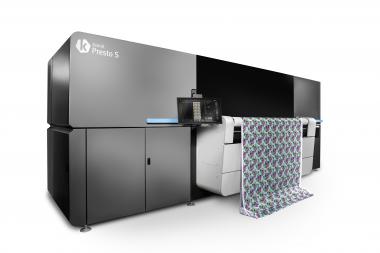

Kornit Digital, (NASDAQ: KRNT), a global market leader in digital textile printing technology, announced today that Chris Govier has been named Managing Director at Kornit Digital Europe GmbH.

Govier is a proven leader who brings broad experience of supporting customers with industrial digital transformation, a proven record of driving growth, and solid experience building and managing world class teams. In his new role, Govier will oversee Kornit Digital’s operations in Europe, the Middle East and Africa (EMEA) and will be instrumental in scaling up Kornit’s business.

Govier previously served in sales and general management roles at Xerox Corporation, and holds a BA from the University of Wellington, New Zealand.

Commenting on the appointment, Gilad Yron, Kornit Digital’s Executive Vice President of Global Business, said, “I welcome Chris on board as the new Managing Director of Kornit Digital Europe. He brings with him solid experience in the analog-digital transition in industrial print and deep regional understanding. Europe has traditionally been a strong performer for Kornit, and Chris’ expertise will help us grow the organization to the next level.”

“This is an incredibly exciting time to join Kornit Digital – their technology, coupled with a passion and drive will significantly disrupt the textile printing industry.” said Chris Govier. “EMEA represents a huge opportunity and I look forward to building on the fantastic success achieved so far.”

Kornit Digital Europe GmbH