BioFibreLoop has been started

The German Institutes of Textile and Fiber Research Denkendorf (DITF) are coordinating the research project, which is funded as part of the European Union's Horizon Europe research and innovation program. The aim of BioFibreLoop is to develop recyclable outdoor and work clothing made from renewable bio-based materials. The kick-off event took place in Denkendorf on June 26 and 27, 2024.

The textile industry is facing two challenges: on the one hand, production must become more sustainable and environmentally friendly and, on the other, consumers are expecting more and more smart functions from clothing.

In addition, the production of functional textiles often involves the use of chemicals that are harmful to the environment and health and make subsequent recycling more difficult.

Intelligent innovations must therefore ensure that harmful chemicals are replaced, water is saved and more durable, recyclable bio-based materials are used, thereby reducing the usually considerable carbon footprint of textile products. Digitalized processes are intended to ensure greater efficiency and a closed cycle.

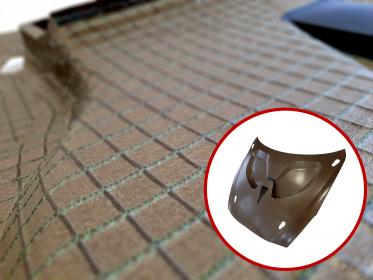

For example, the BioFibreLoop project uses laser technology to imitate natural structures in order to produce garments with water and oil-repellent, self-cleaning and antibacterial properties. At the end result of the research work will be affordable, resource and environmentally friendly, yet high-performance and durable fibers and textiles made from renewable sources such as lignin, cellulose and polylactic acid will be available. All processes are aimed at a circular economy with comprehensive recycling and virtually waste-free functionalization based on nature's example. In this way, greenhouse gas emissions could be reduced by 20 percent by 2035.

The technology for the functionalization and recycling of bio-based materials is being developed in three industrial demonstration projects in Austria, the Czech Republic and Germany. At the end of the project, a patented circular, sustainable and reliable process for the production of recyclable functional textiles will be established.

The BioFibreLoop project has a duration of 42 months and a total budget of almost 7 million euros, with 1.5 million going to the coordinator DITF.

The consortium consists of 13 partners from nine countries who contribute expertise and resources from science and industry:

- German Institutes of Textile and Fiber Research Denkendorf (DITF), Coordinator, Germany

- Next Technology Tecnotessile Società nazionale di ricerca R. L., Italy

- Centre Technologique ALPhANOV, France

- G. Knopf’s Sohn GmbH & Co. KG, Germany

- FreyZein Urban Outdoor GmbH, Austria

- BEES - BE Engineers for Society, Italy

- BAT Graphics Vernitech, France

- Interuniversitair Micro-Electronica Centrum, Belgium

- Idener Research & Development Agrupacion de Interes Economico, Spain

- Teknologian tutkimuskeskus VTT Oy, Finland

- Det Nationale Forskningscenter for Arbejdsmiljø, Denmark

- Steinbeis Innovation gGmbH, Germany

- NIL Textile SRO, Czech Republic

Deutsche Institute für Textil- und Faserforschung