Drupa: touchpoint textile showcases textile printing solutions

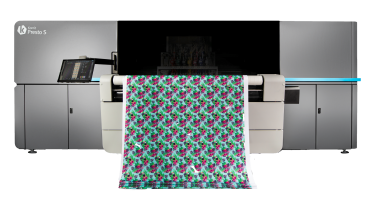

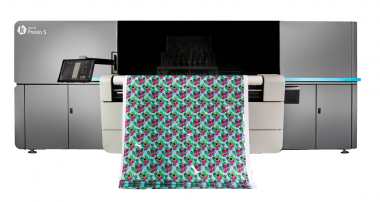

By establishing touchpoint textile, drupa has created a special forum to showcase pioneering applications in digital textile printing. The highlight will be the Digital Textile Micro Factory – a fully connected, integrated process chain starting with the customer enquiry and design through to large-format digital textile printing.

touchpoint textile represents drupa’s growing expansion into new markets comprising such segments as packaging production, large-format or industrial and functional printing next to packaging production. All of these segments are undergoing the same transformation processes and offer enormous growth potential. The special forum revolves around the opportunities and challenges of digital textile printing, brings together renowned exhibitors, industry partners and brand owners and provides scope for cross-industry cooperation, new projects as well as product and manufacturing ideas. The operational content partners of touchpoint textile include the German Institutes for Textile and Fibre Research Denkendorf (DITF), as Europe’s largest textile research centre, as well as ESMA, the European Specialist Printing Manufacturers Association.

Digital Textile Micro Factory: on-demand and virtual products – on the path towards sustainable production

In cooperation with 12 partners from industry and research the DITF will demonstrate a Digital Textile Micro Factory live at drupa and, hence, a fully connected, integrated process chain from design to finished product. This will present new possibilities for digitalisation and direct customer involvement, for instance in the form of 3D apparel simulations complete with links to design networks for creative input. Digital workflows and virtual products are integrated directly in the manufacturing process. As a special highlight for all trade visitors the technology partners of this Micro Factory will demonstrate an automated on-demand production, textile printing, cutting and sorting – without any manual interaction. Such decentralised and digitally connected design and production chains will enable the textile industry to respond to customers’ requests and trends in a more targeted manner in future. This means, touchpoint textile 2024 technologically points the way to a future without shelf-warmers. In addition, the carbon footprint for the complete process from virtual development to finished product will be modelled and presented at the trade fair.

2024 will see the design competition “drupa – textile design talents” being held for the first time. This was conceived of by the DITF and will be implemented by the partner Mitwill. This provides up-coming textile designers and newcomers with a unique opportunity to introduce their ideas and visions to a professional audience.

Broad industry support

A project as comprehensive as the Micro Factory requires many strong partners. The companies “on board” here include: Assyst/Germany (3D simulation for digital apparel twins), Mitwill Textiles Europe/France (creative design network), D.G.I. Digital Graphics Incorporation/South Korea, Multi-Plot Europe/Germany (large-format textile printing), LEONHARD KURZ Stiftung/Germany, Zünd/Switzerland (digital cutting), robotfactory/Denmark, Asco/The Netherlands (presenting an innovative buffer solution between digital printing and cutting, automated sorting of cut parts from the cutter by robotfactory) as well as Brother/Japan (for small-format textile printing and bonding technology). Vaude and berger textiles will be sponsoring the touchpoint. Another key partner is the Albstadt-Sigmaringen University that is supporting the project as a conceptual sponsor and which has set itself the clear mission to incorporate these new topics into its curriculum. This means the staff of the future will be geared up to the new challenges ahead.

Another partner of touchpoint textile is the European Specialist Printing Manufacturers Association (ESMA), which is responsible for the lecture programme. ESMA represents industrial, functional and specialist printing and acts as an organiser of educational events in the field of textile printing. At drupa speakers from research, development, and industry will address issues related to printing and finishing techniques, workflows, market developments and sustainability, to name but a few. The focus will also be on trends and applications that unlock ever new potential through the interplay of digital printing and textile printing substrates. The lectures are divided into the categories Research, Finishing, Print Systems & Hardware, Substrates, Inks & Chemistry and Software & Electronics. Assyst, for example, will deliver talks on the virtual development of apparel as well as the research project ECOShoring, which is funded by the “Deutsche Bundesstiftung Umwelt” – DBU (German Federal Environmental Foundation) and focuses on personalised and on-demand sustainable manufacturing. Other speakers represent Adobe, Balta Group, Barbieri Electronic, Brother, Centexbel, CST, DITF, Fujifilm Speciality Ink Systems, HS Albsig, Kornit Digital, Meteor Inkjet, Mimaki, Mitwill, Multiplot, Print-Rite, RWTH Aachen, Seiko Instruments, Tiger Coatings, Xaar, Zünd and the list is updated on regular basis.

drupa will be held at the Düsseldorf Exhibition Centre from 28 May to 7 June 2024.

Messe Düsseldorf