SGL Carbon auf der JEC World 2020: Neue Lösungen für Automobilsektor, Luftfahrt und Industrie

- Batteriekästen aus Faserverbund für die Elektromobilität

- Flexible neue Blattfeder-Generation für Hinterachse

- Neuartige Bauteilkonzepte für Passagierflugzeuge, Helikopter und Flugtaxis

- Extrem leichter und steifer Transferbalken für den Maschinenbau

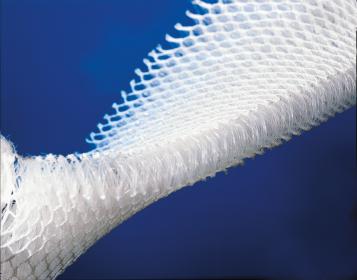

Auf der diesjährigen JEC World, der größten Fachmesse für Verbundwerkstoffe, vom 3. bis 5. März 2020 in Paris stellt die SGL Carbon die serielle Fertigung von Komponenten für die Branchen Automobil, Luftfahrt und Industrie in den Fokus. Entscheidend sind individuelle Lösungen mit innovativen Bauteildesigns und darauf abgestimmten serientauglichen Materialien und Produktionsverfahren. Unter dem Motto „The Solution Provider“ präsentiert das Unternehmen in Halle 6, Stand D25, ausgewählte neue Bauteillösungen aus allen drei Bereichen.

„Dank unserer integrierten Wertschöpfungskette von der Faser bis zum fertigen Bauteil, unserem Lightweight and Application Center sowie unserem zunehmend breiteren Portfolio an realisierten serientauglichen Konzepten bieten wir unseren Kunden smarte, maßgeschneiderte Lösungen aus einer Hand. Unsere umfassende Expertise sowie unsere hocheffizienten Materialien aus dem Automobilbereich setzen wir zukünftig verstärkt auch in der Luftfahrt und im industriellen Bereich ein“, erklärt Dr. Andreas Wöginger, Leiter Technologie des Geschäftsbereichs Composites – Fibers & Materials bei der SGL Carbon.

SGL Carbon