10,460 kilometers: First direct complete train with Austrian TENCEL™ branded fibers from Vienna to China

- Due to the short-term increase in demand from Chinese customers, Lenzing AG is breaking new ground. For the first time in the history of Austria, a local company is sending goods that are 100 percent produced in Austria directly to China by train.

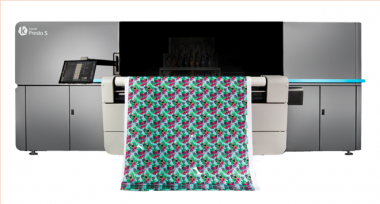

Vienna – The Lenzing Group stands for the ecologically responsible production of specialty fibers made from the renewable raw material wood. Due to the high demand from Chinese brands and retailers for sustainably produced fibers, Lenzing delivers fibers from the two Austrian production sites Lenzing and Heiligenkreuz directly to customers in China by train for the first time.

Austria's first complete train with goods exclusively “Made in Austria” will leave the Vienna South Terminal towards China on August 20, 2020 at 11 am. The train is loaded with Lenzing fibers and provided by NUNNER Logistics. In strict compliance with the COVID-19 protective measures, Leonore Gewessler, Federal Minister for Climate Action, Environment, Energy, Mobility, Innovation and Technology, His Excellency Xiaosi Li, Ambassador of the People's Republic of China in Austria, Stefan Doboczky, CEO of the Lenzing Group, Thomas Kargl, Board Member of the ÖBB Rail Cargo Group, Erwin Cootjans, CEO Nunner Logistics and Erich Hampel, Chairman of the Board of the B&C Private Foundation, took part in the departure ceremony.

The train, which started at Vienna, brings 41 containers with TENCEL™ branded Lyocell and Modal fibers with a total value of EUR 1.8 million directly to customers in China. On its 16-day trip to Shanghai, the train covers a total of 10,460 kilometers and passes seven countries: Austria, the Czech Republic, Poland, Belarus, Russia, Kazakhstan and China. “With this new transport route, we can meet the high demand from our customers for sustainably produced fibers more quickly. Thanks to train transport, the urgently needed fibers arrive at our customers in China twice as quickly as by sea freight,” says Stefan Doboczky, CEO of the Lenzing Group. Lenzing has had very good experiences with rail transport for a long time when it comes to delivering the renewable raw material wood to its plants. Almost 70 percent of the wood processed at the Lenzing site is already delivered by rail. “Our declared goal is to shift more freight traffic to rail. Rail is the only way to combine climate goals and economic interests and thus transport growth. That is why we are happy to be part of this unique project for our long-standing customer,” says Thomas Kargl, Board Member of the ÖBB Rail Cargo Group. “Transporting goods by rail to China is possible. And this train from Vienna to China is an integral part of climate protection. Because we want to support the shift from road to rail, especially in freight transport. Today's train is the first step – I am convinced this train will set an example”, says Leonore Gewessler, Federal Minister for Climate Action, Environment, Energy, Mobility, Innovation and Technology.

Lenzing Aktiengesellschaft