Introducing NeoPigment™ Robusto Softener Solution for Kornit Presto

Join this webinar session with Kornit CEO Ronen Samuel and CMO Omer Kulka that will take place on Monday, 23rd March 2020 at 2:00 PM CET. To learn more about what the Softener is, how it works, and why it presents a great many opportunities for making the fashion industry more eco-friendly, more reactive to emerging demands, and more conducive to efficient and versatile business models.

We'll be presenting you with:

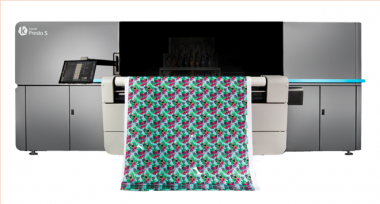

- our new NeoPigment™ Robusto Softener solution for Presto, the company’s system for digital, pigment-based roll-to-roll direct-to-fabric decoration. Kornit’s pigment-based print process can help companies achieve their sustainability goals. Traditional rotary reactive ink six-color printers use 60-80 liters of water per linear meter, and digital reactive ink for fashion designs use 14-40 liters; Kornit’s award-winning* NeoPigment™ Robusto ink set, which is both GOTS and ECO PASSPORT by OEKO-TEX® certified, is waterless.

- the Presto - Kornit’s Presto solution eliminates the need for pre- and post-treatment of fabric and allows for high-quality printing on an extraordinarily broad variety of fabric types and applications.

Please register for our webinar Here

Kornit Presto

Pr4u