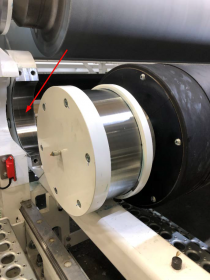

Perlon® production is still running at all sites in Germany, the USA and China

Perlon®, a Serafin Group company, is continuing to produce its’ quality filaments at all five sites for its’ customers in the current challenging climate. Production in China has been operating again as normal since the beginning of March after having to be temporarily halted due to the spreading of Covid-19. Production is now back up to 100%.

Production in Germany at our sites in Munderkingen (Baden-Wuerttemberg), Bobingen (Bavaria) and Wald-Michelbach (Hesse) as well as in the USA is continuing to run without any constraints. Therefore all sites are working to full capacity. In particular in the paper machine clothing area is showing an increase in sales which offsets a reduced demand in other areas such as automotive.

To manage the current situation responsibly, all hygiene measures at all our sites have been significantly increased so that the employees are protected as well as possible. There is hand sanitizer in every department and all of our production lines are disinfected several times a day. It has been explained to employees, what they should do in the current climate in order to minimise risk. Where possible employees are able to work from home. Perlon® has approximately 650 employees in Germany, over 80 in the USA and more than 100 in China.

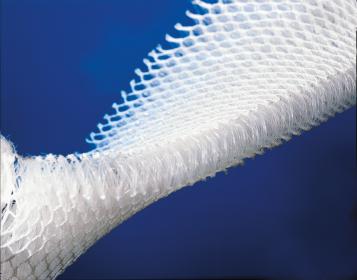

High demand for monofilament for the paper industry

The paper industry is currently experiencing a rise in demand worldwide – and Perlon® is also benefitting from this, as customers need even more high quality monofilament and twisted yarns for the tensioning of paper machines. For the paper machine clothing field, Perlon® produced filaments are used to manufacture press fabric, which can be used either as a conveyor belt or for moisture removal on a paper production line. Due to the high mechanical strain through the presses, polyamide monofilaments or twisted yarns are therefore almost always used. Paper industry customers have increased their production recently. Whether it’s boxes to cope with the increased demand for online deliveries or paper for hygiene purposes (which everybody can identify with), there is an increased demand worldwide. The dental, hygiene and food preparation fields are also experiencing increased demand. To this end, Perlon® offers filaments for the manufacture of toothbrushes and high quality cleaning system brushes.

Perlon®