Cinte Techtextil China 2022 confirmed for September

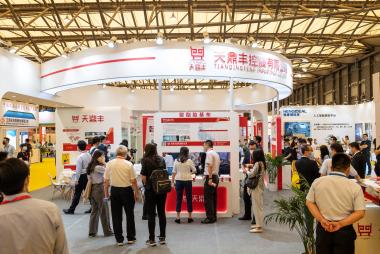

The 2022 edition of Cinte Techtextil China has been confirmed to take place from 6 – 8 September at the Shanghai New International Expo Centre. 2021 saw 366 exhibitors and 14,868 visits recorded at the June hybrid event, which offered in-person and digital options for suppliers and buyers.

This year’s edition of Cinte Techtextil China marked the first time the fair was held annually, and the second year physical and online participation options were available, with both aspects well received by exhibitors and visitors.

Ms Wendy Wen, Senior General Manager of Messe Frankfurt (HK) Ltd elaborated: “The response from our exhibitors this year was the Chinese market is still growing strongly, and having an annual edition allows them to benefit from these opportunities on a more regular basis. The domestic economy has shown strong resilience over 2020 and so far in 2021, and this has allowed the technical textiles and nonwovens sector to maintain the growth momentum it has experienced over the past years. As more economies return to normal in 2022, we expect export orders for the sector to receive a further boost which will benefit those overseas companies with business in the Chinese market.”

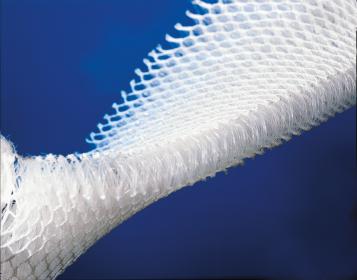

Cinte Techtextil China’s product categories cover 12 application areas, which comprehensively span the full range of potential uses of modern technical textiles and nonwovens. These categories also span the entire industry, from upstream technology and raw materials providers to finished fabrics, chemicals and other solutions.

Messe Frankfurt Messe Frankfurt HK, Ltd Cinte Techtextil China nonwovens Technical Textiles

Messe Frankfurt (HK) Ltd