coldblack®: Schoeller cooperates with Südwolle Group

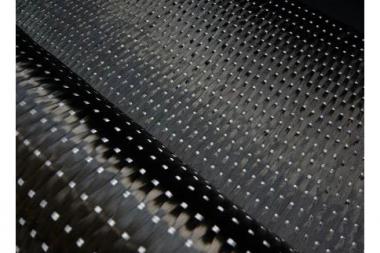

OutDoor2018: Schoeller’s coldblack® technology has been specifically optimized for use on knitted and woven fabrics so brands can now expand their product application uses. Under the blazing sun, textiles with coldblack® heat up less and stay cool to the touch. Südwolle Group, a leading manufacturer of high quality yarns, has also recognized the ideal combination of merino and coldblack®. With this, the wear comfort of wool apparel can be tangibly improved.

Wool is well known for its various property benefits, including insulation, natural antibacterial protection, odor control, light weight and nearly wrinkle free composition. Not only in the winter time, but also in summer particularly merino wool, a special high-quality type of wool, regulates moisture balance and thus the body temperature. The fibers can absorb a great deal of moisture or sweat and transport it away from the body. Warm ambient air quickly dries the material and causes a cooling evaporation, which makes it very comfortable to wear merino apparel in the summer time.

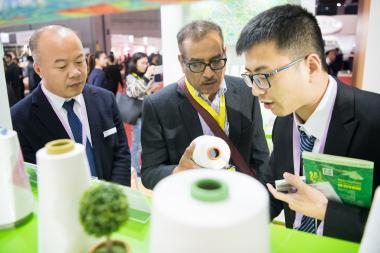

coldblack® technology from Schoeller supports the natural properties of wool because it reliably reduces heat build-up when exposed to the sun. Together with the help of Südwolle Group, the finish has been optimized specifically for the use in merino apparel. The yarn manufacturer chooses coldblack® for a variety of uses, especially for knitting and weaving yarns for sports and outdoor apparel and develops such products individually according to its customers’ requirements.

Stéphane Thouvay, Managing Director Product Management & Innovation at Südwolle Group, summarizes the use of the technology as follows: “coldblack® is part of our product range for the summer time, which we will be presenting at OutDoor show in Friedrichshafen. The technology reduces not only heat build-up, but also enhances the natural UV protection of wool without affecting the look and feel of the fabric. Therefore coldblack® perfectly fits into our yarn selection for sports and outdoor apparel, for example in our collection ʻYarn in Motion’. For end consumers garments made of coldblack® yarns can optionally be labeled with hangtags.”

When used in high-quality woolen fabrics, coldblack® has already proven its performance and is being used by renowned brands in various collections of men’s suits. Since 2008, the technology has been licensed by more than 200 brands, in sports particularly in the field of cycling, triathlon and golf. All components of the finish are bluesign® approved.

Schoeller Textil AG