Manteco presents The Manteco System

The integrated sustainable network making fashion circular, Made in Italy and 100% traceable

World leading textile manufacturer Manteco presents its sustainable path for a better future: The Manteco System. A strategy and a vision shaping the company’s sustainable imprint since 1943. The system consists in the development and engineering of a production network involving 100 partner-companies from the whole supply chain “We all team up responsibly to create premium collection based on transparent , traceable circular economy practices,” comments Matteo Mantellassi, co-CEO of Manteco.

To achieve meeting the demand for fair and sustainable fashion that consumers believe in, and is expected from our clients, the company and its partners have created and accomplished to a Protocol of Sustainable Values and Commitments in line with the highest standards of the global market.

“On a hand, the protocol preserves the unique ‘genius loci’ of our territory – it respects the heritage of all our partners, from the smaller businesses to the more structured ones - on the other hand, it works like a shared compass of sustainable values, allowing the whole supply chain behind Manteco products to stand out and be competitive on the global stage” adds Mantellassi.

The protocol and its monitored and traceable system cover virtuous management of resources – e.g. Water, energy and chemical products - waste management and low production impact on the environment but also responsible standards in terms of employment, quality of the working environment, equal rights and anti-discrimination policies.

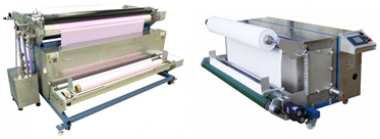

One of the key results of such commitment and sustainable development is the creation of an upgraded version of the recycled wool MWool™: a top ingredient made from premium recycled wool process guaranteed by the Manteco System.The System works like a symphony where management, measurement and controls are not there just to test the quality of each single phase of processes or products , but to make sure and offer the complete traceability of Manteco production. From raw material, to yarn, spinning, finishing, testing and final fabric.

Some productions tips about Manteco:

- 5.3 million kg of raw materials processed annually.

- 6.860 tests on raw material per year.

- 34.400 tests on finished products.

- 100% made in Italy system completely based in the Prato district since 1943.

- Total transparency and traceability thanks to a highly skilled management system.

With a turnover of over 91m Euro in 2019 and an annual growth of 17,80% since 2012, Manteco SpA is the 4th textile company in Italy, listed in the TOP30 companies of the Italian fashion system. “The unique Manteco system adds value to our products while highlighting the sustainable path we share with all our partners both upstream and downstream”.

Manteco

(c) GB Network