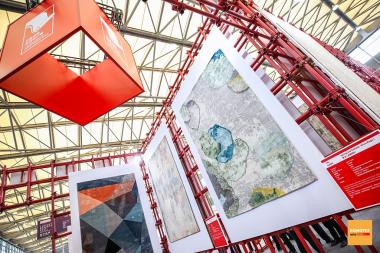

M.O.D.E. x Denim PV: an exclusive exhibition to explore the history of denim

- Elleti Group takes center stage at Denim PV to present a special project realized in partnership with MYR, and to share a selection of iconic garments belonging to M.O.D.E, the company’s Museum of Denim.

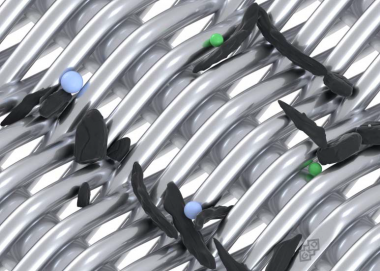

- Collaboration will be the main theme of the two-day event, involving not only the leading company’s expertise in garment-making but also its tradition, starring M.O.D.E in its firstever collaboration with a trade show and in Alessio Berto’s RE-TRACE workshops series.

London – When it comes to long-established traditions in the denim industry, Elleti Group stands out as one of the main key players: strong in the business since the 80’s, the company is highlyspecialized in laundry and garment-making services while covering the entire denim production cycle in its eleven production hub.

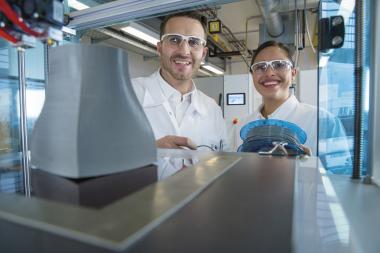

Its heritage and approach define a valuable and renowned legacy that is now taking stage at Denim PV on December 3rd and 4th. For the occasion, Elleti Group joined forces and knowledge with MYR, start-up program conceived to digitalize the creative process and connect users, suppliers and final consumers through a digital platform. Both companies will be in the Garments and Finishings area - booth C3, howcasing an exclusive project to highlight their creativity and competences.

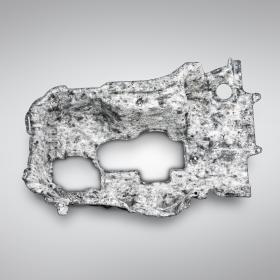

Starting from a selection of bold designs, entirely envisioned and developed with MYR software, Elleti Group worked to recreate their look and fit on six garments, manufacturing each piece according to its signature innovative and responsible approach. Featuring forefront machinery and cutting-edge processing solutions, this relies on a continuous research effort focused on granting high-quality products while increasingly reducing their knock-on effect on both workers and the environment.

The result turned out to be very impactful and inspiring, with denim solutions which proved the mastery of the leading Italian company in the art of washing, cutting and stitching the iconic blue fabric, as well as the great support that MYR software provided in the development of the collections.

M.O.D.E. x Denim PV: an exclusive exhibition to explore the history of denim

Opened on June 19th, M.O.D.E. – Museum of Denim Elleti Group – is a precious resource located within the company’s Headquarters in San Bonifacio (Italy). Here are 106 pieces dating between the second half of the XIX century and the 70s, resulting in an invaluable testimony of how denim evolved through the centuries. For the first-ever collaboration of the Museum with a trade show, a selection of 20 historical garments is exploring three research areas. These are meant to focus on:

- The brand identity of jeans through the main evolutions at Lee;

- The influence of WWII on the design, the creation and the wearing of clothing;

- The history of overall.

Menabò Group