Lenzing appoints new Executive Vice President of Commercial Textiles

Lenzing Group announces the appointment of Kit Ping Au-Yeung as the Executive Vice President of Commercial Textiles with immediate effect. This strategic leadership appointment highlights Lenzing’s commitment to strengthen its integral leadership roles and fuel the growth of its core textile businesses. Kit Ping succeeds Florian Heubrandner, who will take on a new role as Executive Vice President of Filament to reinforce the expansion of Lenzing’s global filament business.

In her new role, Kit Ping will be leading the expansion strategy and development of Lenzing’s textiles business, which comprises of fiber offerings under the flagship TENCEL™ and LENZING™ ECOVERO™ brands. With decades of experience working with partners across the textile value chain, Kit Ping will continue to foster the development of Lenzing’s textile business through driving innovative fiber and application solutions for customers, and ultimately bring benefits to consumers. Prior to joining Lenzing, Kit Ping held several regional and global commercial and operational leadership roles at Coats Group, as well as more recently at Amann Group. Her experience will add value to Lenzing’s core business, affirming Lenzing’s dedication to driving a positive impact across the industry ecosystem.

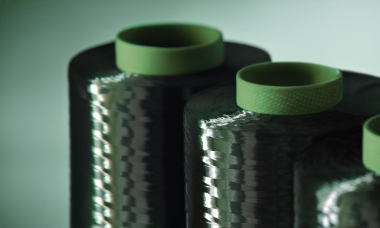

From 1 July 2024 onward, Florian Heubrandner will focus on driving the strategy and expansion of Lenzing’s filament business with his established expertise in the value chain. He will work alongside Lenzing’s Research and Development and Engineering teams to establish filament as a separate business with a strong focus on innovation and growth.