Wie Digitalisierung und KI die vernetzte Produktion im Mittelstand ermöglichen - Unternehmer sprechen zu Unternehmern

Seit drei Jahren unterstützt das Mittelstand 4.0-Kompetenzzentrum Textil vernetzt erfolgreich kleine und mittlere Unternehmen beim Thema Digitalisierung. Knapp 50 Praxis-Projekte hat das Kompetenzzentrum umgesetzt und weit über 3 000 KMU mit seinen Angeboten erreicht. Vielen Unternehmen hat das Netzwerk bereits beim Sprung in die Zukunft geholfen, wie die Teilnehmer der dritten Fachtagung hautnah erleben konnten.

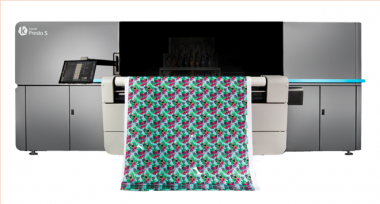

Es war die erste Online-Fachtagung. Gastgeber und Organisator war das Sächsische Textilforschungsinstitut e. V. (STFI) in Chemnitz mit dem Thema: „Textil neu denken: Wie Digitalisierung und KI die vernetzte Produktion ermöglichen“. Die Fachtagung stand ganz im Zeichen der vernetzten Produktion, der Digitalisierung und Automatisierung von Produktionsprozessen. So ging es beispielsweise um die durchgängige digitale Auftragsabwicklung. Oder darum, welche Vorteile Bilderkennung und Barcode bei der Lagerortbestimmung haben. Der Einsatz von Sensortechnik eignet sich zum Sammeln und Auswerten großer Datenmengen: So kann die Wartung von Maschinen vorausgesagt werden. Das spart Kosten und Arbeitskraft.

„Die Unternehmer haben sehr offen darüber geredet, vor welchen digitalen Herausforderungen sie standen, wie Textil vernetzt unterstützen konnte und welche weiteren Schritte geplant sind“, zieht Geschäftsführerin Anja Merker nach der Veranstaltung Bilanz. „Durch Corona hat die Digitalisierung einen Schub erfahren. KI-Anwendungen werden von unserem textilen Mittelstand bei den Textil vernetzt-Partnern zunehmend nachgefragt“, so Merker. Gerade unkonventionelle und KMU-orientierte Herangehensweisen sind es, die von den Unternehmern geschätzt werden, so die Quintessenz der Veranstaltung. „In unserem neu eröffneten EscapeROOM können Unternehmen spielerisch KI erleben“, resümiert Claudia Feith vom Textil vernetzt-Partner Hahn-Schickard.

An die Partner Deutsche Institute für Textil- und Faserforschung (DITF), Hahn-Schickard, Institut für Textiltechnik (ITA) der RWTH Aachen sowie Sächsisches Textilforschungsinstitut (STFI) unter Leitung des Gesamtverbandes textil+mode wenden sich kleine und mittlere Firmen aus Industrie und Handwerk. Die Unternehmer kommen dabei mit individuellen Fragestellungen auf Textil vernetzt zu und werden von den Projektpartnern bei der Digitalisierung unterstützt.

Gesamtverband der deutschen Textil- und Modeindustrie e. V.