Groz-Beckert at INDEX™23

Groz-Beckert will be presenting the latest innovations from its product area Carding to visitors at INDEX™23

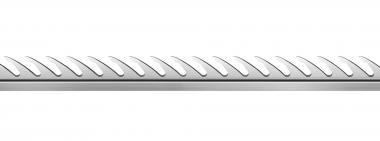

The InLine card clothing series for the nonwovens industry will take center stage at the Groz-Beckert exhibition booth. A new and patented manufacturing process made the development of the innovative metallic card clothing series possible. It offers customers improved process reliability and increased uptime of the card. At the same time, the new process enables environmentally friendly and resource-saving production.

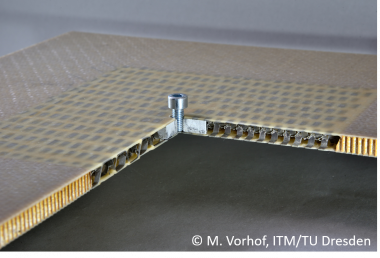

In addition to a controlled and precise hardening of the teeth, the wires are characterized by a reduced rib height and a completely scale-free surface. An exhibit at the booth will demonstrate what distinguishes the new process from the conventional production method and will highlight the differences between the new Groz-Beckert InLine card clothing series and its predecessor generation.

The first special geometry of the Groz-Beckert InLine card clothing series to be developed was the SiroLock™ plus worker and doffer wire. It impresses with a more effective fiber take-up, control and transfer. Augmented reality will allow visitors to experience the functionality and operating principle behind SiroLock™ plus at INDEX™23.

Groz-Beckert