Haelixa Raises EUR 2 Million to Scale DNA-Based Traceability Globally

Haelixa, the Swiss-based deeptech provider of DNA-based product traceability, has raised EUR 2 million in a pre-series A investment round to support international scale and long-term strategic growth.

The round was led by existing backers Verve Ventures and Zurich Kantonalbank, with participation from an impact-focused investor 212 NexT Fund. This complements the catalytic funding awarded through the Temasek Trust Amplifier programme.

The investment will support Haelixa’s international expansion, targeted team growth, and deeper collaboration with textile brands and supply-chain partners.

Physical Proof in an Era of Rising Risk

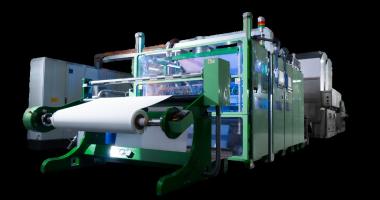

Haelixa’s patented DNA-based technology physically marks raw materials at any stage of production and enables later verification of origin and authenticity. The plant-based, invisible DNA markers are embedded directly into raw materials and remain detectable throughout complex, multi-tier supply chains.

As regulatory scrutiny increases, fashion brands face growing risks of fraud, undeclared blending, and substitution of premium materials, as well as mounting exposure to counterfeiting. These failures threaten compliance, brand equity, and consumer trust. By enabling verification directly on the product itself, Haelixa provides brands with a practical safeguard to protect material integrity and brand value.

Haelixa’s technology is already used across fashion and textiles, as well as precious metals and gemstones, and is compliant with GOTS, Standard 100® by OEKO-TEX, and OEKO-TEX® Eco Passport.

From Innovator to Investor-Backed Scale

Haelixa originated as a spin-off from ETH Zurich and has since achieved scaled commercial adoption, generating seven-figure revenues and securing multi-year agreements with leading textile and fashion brands.

Haelixa