SGL Carbon: Review of options for Business Unit Carbon Fibers

SGL Carbon SE is currently evaluating various strategic options for the Business Unit Carbon Fibers (CF). These include a possible partial or complete divestment of the Business Unit. In a first step, potential interested parties shall be approached with the general data of the Business Unit to determine their interest in an acquisition. If there is sufficient interest, a structured transaction process will be carried out in a second step. Overall, a share of sales amounting to around € 179.6 million after nine months in 2023 (9M 2022: € 269.0 million) is therefore under review. The CF sales share corresponded to 21.9% of SGL Carbon's consolidated sales after nine months in 2023 (9M 2022: 31.5%). Adjusted EBITDA of the Business Unit excluding the result from joint ventures amounted to minus € 10,9 million after nine months in 2023 (9M 2022: € 27,9 million). Despite the operating loss of CF after nine months in 2023, SGL Carbon maintains its guidance for fiscal year 2023. This shows the positive development of the three other business units and the resilience of SGL Carbon's business model.

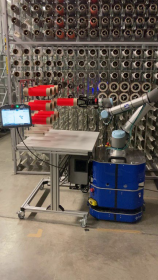

Carbon Fibers manufactures textile, acrylic and carbon fibers as well as composite materials at seven locations in Europe and North America. Following the temporary drop in demand for carbon fibers from the important wind industry market, the Business Unit's sales and earnings fell significantly in the course of fiscal year 2023. Due to the importance of the wind industry for the European Green Deal, SGL Carbon and many experts assumed that the wind industry recovers quickly. Unfortunately, this is currently not the case. Even if demand picks up, the company assumes that Carbon Fibers will need additional resources to remain competitive in the international market environment and to exploit market opportunities in the best possible way. Against this background, SGL Carbon is reviewing all possibilities to support a positive further development of the Carbon Fibers Business Unit.

SGL Carbon SE