Fashion for Good welcomes new partners to its Sorting for Circularity USA Project

The Sorting for Circularity USA consortium project welcomes new partners and expands its North American geographical scope. Fashion for Good is pleased to announce the addition of lululemon as an external brand partner, joining the existing seven brand partners. They also welcome their new implementation partners Helpsy, United Southern Waste Material, Goodwill Industries International Inc., and its members Goodwill of Colorado, Goodwill Industries-Suncoast, Inc., Goodwill of the Finger Lakes, and Goodwill of San Francisco Bay. Additionally, Fashion for Good is pleased to recognise adidas as the project's lead sponsor, facilitating the complete realisation of the project scope.

Fashion for Good, together with Resource Recycling Systems, launched the Sorting for Circularity USA consortium project in January 2023. The project will conduct an extensive consumer survey to map the journey of a garment from closet to end of use, and present a comprehensive snapshot of textile waste composition generated in the United States. The insights gained from this 18-month project will help to scale collection, sorting, and recycling innovations and inform decisions on necessary investments and actions.

Within the first 6 months, the project has expanded to cover 6 key states: California, Texas, Florida, New York, New Jersey and Colorado. Additional implementation partners have also signed on to support the fibre composition data analysis: Secondary Materials and Recycled Textiles (SMART) Association, Helpsy, United Southern Waste Material, and Goodwill Industries International Inc., with its members Goodwill of Colorado, Goodwill Industries-Suncoast, Inc., Goodwill of the Finger Lakes, and Goodwill of San Francisco Bay. Resource Recycling Systems will drive the dissemination and analysis of the consumer survey together with New York State Center for Sustainable Materials Management and Syracuse University Center for Sustainable Community Solutions, and execute the textile composition analysis using Matoha’s near infrared devices with advisory support from Circle Economy.

Demonstrating the importance of pre-competitive collaboration in tackling the industry’s biggest challenges, lululemon joins Eastman, H&M and Nordstrom as key project partners, together with Fashion for Good corporate partners adidas, Inditex, Levi Strauss & Co., and Target. Adidas' lead sponsorship ensures a deeper analysis of USA textile waste infrastructure and the identification of valuable opportunities for advancement.

In the USA, textile waste is the fastest-growing segment of the country's waste stream, with 85% of discarded textiles ending up in landfills*. Understanding the composition of material, volume and location of used textiles is crucial for capturing them and sorting them for the best and highest quality end use. Moreover, the range of national and regional geographies within the Sorting for Circularity project series enables for nuanced cross-country comparisons - revealing differences in the textile waste generated and infrastructure required.

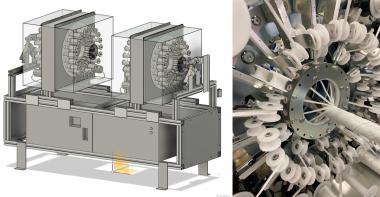

Sorting for Circularity, a framework co-developed by Fashion for Good and Circle Economy, aims to (re)capture textile waste by unlocking the feedstock potential for recycling, expedite the implementation of game changing automated sorting technologies such as near-infrared spectroscopy and advanced textile-to-textile recycling, and drive circularity within the fashion value chain. The project builds on the success of Sorting for Circularity Europe and India, which revealed insights on material composition, volume, and location of used textiles and provided a solid foundation to accelerate textile recycling in those respective geographical locations.

*United States Environmental Protection Agency (2019). National Overview: Facts and Figures on Materials, Wastes and Recycling.

Fashion for Good