SHIMA SEIKI at SPINEXPO 40th Session Shanghai

SHIMA SEIKI MFG., LTD. of Wakayama, Japan, together with its Hong Kong subsidiary SHIMA SEIKI (HONG KONG) LTD., will participate in the 40th Session of SPINEXPO in Shanghai, China from 12th - 14th April 2023.

At SPINEXPO, SHIMA SEIKI will offer visitors a choice between its "SDS®-ONE APEX4" apparel design system and its "APEXFiz®" subscription-based design software. Whereas SDS®-ONE APEX4 is offered as an all-in-one proprietary hardware + software package, APEXFiz® is subscription-based design software that can be installed on customers' individual computers. Both SDS®-ONE APEX4 and APEXFiz® software support the creative side of fashion from planning and design to colorway evaluation, realistic fabric simulation and 3D virtual sampling. Virtual samples are a digitized version of sample making that are accurate enough to be used effectively as prototypes, replacing physical sampling and consequently reducing time, cost and material that otherwise go to waste. When a design is approved for production, knitting data is automatically generated for converting to machine data, allowing smooth communication for digitally bridging the gap between studio and factory. APEXFiz® thereby helps to realize sustainability while digitally transforming the fashion supply chain.

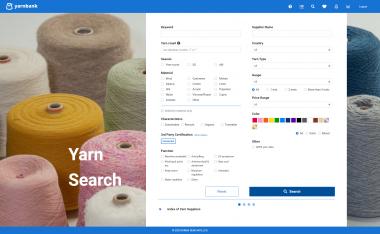

Also on display at SPINEXPO will be SHIMA SEIKI's "yarnbank®," an online web service for searching and viewing the latest yarns, developed with cooperation from yarn companies from around the world. Registered users can download yarn data for free, for use in fabric simulation and virtual sampling on APEXFiz®, avoiding the need to scan yarn on their own. By using yarn that is used in actual production, designers and apparel companies can furthermore rest assured that the simulations created using yarn from yarnbank® are not merely realistic images but accurate representations using yarn that can actually be purchased and used in production. With yarnbank®, the entire supply chain from yarn companies and apparel companies to knit manufacturers can be connected digitally.

SHIMA SEIKI will also display the latest collection of its knit samples, including WHOLEGARMENT® knitwear that is knit in its entirety on the machine without the need for linking or sewing afterward. Together with virtual sampling performed on APEXFiz®, WHOLEGARMENT® offers smart production for realizing a sustainable fashion supply chain.

SHIMA SEIKI MFG., LTD.