adidas: Y-3 Spring/Summer 2024 Chapter 2

For the second chapter of their Spring/Summer 2024 collection, adidas and Yohji Yamamoto continue to explore the concept of Contra-Natural. The collection highlights the tensions at the heart of Y-3: sport and boundary pushing design, organic and synthetic, linear perfection and natural imperfection.

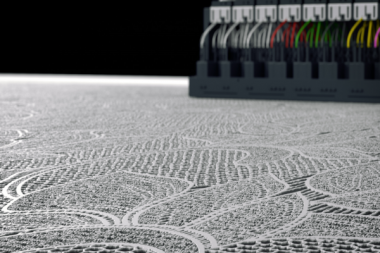

For Chapter 2, Y-3 introduces a selection of dynamic apparel looks with a focus on refined cotton twill workwear inspired garments and reimagined sporting classics. Subtle yet bold overshirts, cargo pants, and tops are constructed with utility pockets and adjustable hems, while updated takes on the iconic adidas Superstar Tracksuit are elevated with topographical map piping. A selection of garments inspired adidas’ Teamgeist soccer jerseys rounds out the apparel collection, with each piece bearing a digital rust print inspired by the natural process of oxidation. Accompanying the apparel offering is a suite of accessories including nylon backpacks, totes, and holdalls.

From apparel to footwear, the second seasonal chapter plays host to an expressive selection of silhouettes as adidas performance Running technology is recontextualized through the lens of Y-3. Moving boldly into tomorrow, Yohji Yamamoto’s take on adidas’ pinnacle running silhouette takes the form of the Y-3 PRIME X 2 STRUNG, while the Y-3 ADIOS PRO 3.0 arrives in three colorways.

From the past, reborn, to the future, the Y-3 Spring/Summer 2024 Chapter 2 collection is then punctuated by the Y-3 WATER SLIDE, the Y-3 SANDAL, and an update to the instantly recognizable Y-3 ITOGO which sees the silhouette’s straps swapped out for an engineered print.

adidas AG